With a dedicated technical team, STANDARD INDUSTRIE International carried out the cleaning intervention. Thanks to constant monitoring of the extraction during cleaning work and constant communication on the work progress with the final client, the results of the intervention were positive and allowed the client to have a cleared silo for the next maintenance work to take place. NPC is pleased with the GIRONET® intervention because of its maneuverability, its safety and its efficiency.

Context of the intervention: 2500 tons Cement Silo 5 with 575 tons estimated build-ups – 30m high, 10m in diameter, inverted cone inside the silo with aeration pads + air slides as extraction. Max output of 150 tons/hr. No cleaning for the past 10-12 years. So, 30 days of cleaning service with the GIRONET® was necessary.

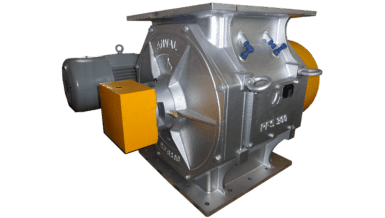

GIRONET® details: In case the plant faces reduced collection capacity, the use of the pneumatic GIRONET, proposed by Standard Industrie International, will help to clean the silos and allow to get the whole storage capacity back.

The articulated arm of the GIRONET® which rotates at 360° eliminates the rat holing problems. This solution meets stringent safety standards: It avoids having any human presence inside silos.

The GIRONET® intervention will enable to increase the capacity of collection to avoid supply disruptions.

The GIRONET® is effective on any type of blockage, product, or storage unit. It can be used without stopping production.

Other types of using the GIRONET:

- Cleaning a reactor in an incineration plant

- Silo cleaning of soda ash in glass factory

- Elimination of a material crust on the walls of the plaster storage silo

- Cleaning of flour and cereal silos