Although moisture content usually dictates the appropriate feeder, it is important to understand how the material reacts after being agitated. Regarding the drying application mentioned above, the customer discussed drying 43% moisture Tricalcium Phosphate filter cake. Upon initial review, the material still had powdery characteristics even at 43% water content. After simply working by hand, the material started to release its water. At this point, the flowability of the product may contribute to difficulty in successfully feeding by a screw conveyor. This simple assessment led to the recommendation of a Scott Equipment Cake Feeder as the primary choice of feeder to consider. More information on the Cake Feeder can be found HERE.

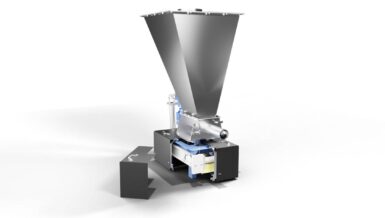

Another consideration that customers specify is the ease of maintenance inherent to their drying system feeder. Some materials can be limited in their free-flowing ability and have a steep angle of repose (>60 degrees). The Scott Equipment Mixer Feeder may be a candidate for lower maintenance and a feeder that can handle virtually any material. The Mixer Feeder incorporates an agitator that stops the material, such as a fine, sticky powder, from bridging over the screw feeder.

In cases where agitation would not benefit the process, other factors must be considered. Another important element of selecting the right feeder is the rate at which the drying system needs to operate continuously. Continuous industrial processes may benefit from surge capacity. At times, it may not be economically feasible to design a feeder incorporating the appropriate surge capacity level. When upstream processes may be variable, surge capacity is crucial. When you combine this factor with material that tends to bridge or is found to be sticky or prone to developing cohesive masses, a live bottom bin feeder may be a solution. A Live Bottom Feeder typically has multiple screw augers located at the bottom of a hopper and is quite effective in its ability to meter high amounts of material when compared to other means of feeding.

Selecting the right feeder for your drying application requires thoughtful consideration of material characteristics, maintenance needs, and overall processing requirements. It is important to note that each drying application that customers inquire about with Scott Equipment goes through a thoughtful process to ensure that requirements for efficiency and reliability are met. Reach out today to get started with your drying application!