Due to the fast development of the building and quarry industry in many European countries during the past years, the demand for more solution approaches for applications of cement plants has increased. Solutions of appropriate sensor technology for content and point level measurement have to be found in order to support the process flow of the cement production in the most reliable way.

A manufacturer of concrete and plaster products for the building industry in Italy wanted to modernize his process flow with a redesign of the measuring equipment. Pre-dosed products are mainly offered, which are supposed to make life on the construction site easier. The manufacturer was amongst others looking for a reliable level measurement system for his new cement storage silos. The requirements for the sensor were not easy. The environment is very dusty and sticky and the surface of the cement is after filling or during emptying with a steep angle of repose.

When it comes to cement product storage the technology needs also to deal with moisture prone to clumping of sticky materials and low density and low dielectric constant. Further there occurs condensation in winter that might affect the measurement. There is a need for the equipment to be safe and reliable, with high availability, easy to install, no leakage, maintenance-free and certified.

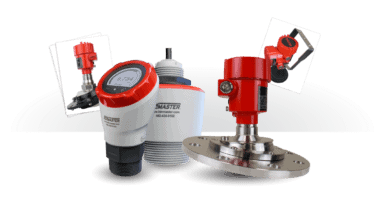

Together with the local partner SMERI S.R.L the team from UWT Level Control thus tested by actual application conditions different technologies that have been already successfully applied in extremely dusty process environments. The configuration of measurement technology for the storage silos was finally made with the free-radiating radar sensor NivoRadar® NR 3100 that has to fit to the special installation demands. The measuring device has to cope with measuring distances up to 19 meters and DK values of 3 – 4. During filling processes there are extremely dusty, polluted environments. There were process temperatures of up to 80°C (176°F) with 0,8bar (11,6psi) pressure.

The 78 GHz technology of the radar sensor has a 4° narrow radar beam and guarantees a reliable level signal in the single chamber silos. Also during filling the reflection from the surface of the material has a high echo confidence.

Electromagnetic waves form the basis of level measurement with radar. A radar sensor emits a focused electromagnetic wave that is reflected by objects as an echo and is then evaluated by the sensor. In addition to free-radiating radar sensors, the radar category also includes those based on guided microwave technology, which are referred to as guided radar, TDR (time domain reflectometry) or also GWR (guided wave radar) sensors. The fundamental difference between free-radiating sensors and guided radar sensors is the way the electromagnetic waves reach the medium to be measured. While free-radiating radar sensors use special types of antennas to transmit the waves in the direction of the material without contact, guided radar sensors require a probe (rod or cable) as a waveguide along which the signal is guided to the medium. The probe is in contact with the medium. Free-radiating radar sensors are generally characterized by their frequency, since this is important for non-contact level determination in process or storage vessels. Radar sensors with high frequencies can be built more compactly, have smaller radiation angles and better reflection properties, which ultimately leads to precise and reliable measurement results.

The combination of a high dust generation and adhering material characteristic were no challenge for the radar transmitter as the air purge connection allows regular, cyclical cleaning of the lens antenna. The commissioning with the quick start wizard was simple and intuitive. That makes the NR 3100 the right choice of instruments in the cement storing application. The integrated aiming flange allowed the sensor to be perfectly aligned to the desired position on the roof of the silo.