Understanding Bulk Solids Mixing Technology

Bulk Solids Mixing Technology is a cornerstone in the industrial world, dealing with the homogeneous blending of powders to ensure product quality and consistency. The journey of this technology over the past three decades has been marked by significant advancements. Engineers today have at their disposal an array of sophisticated equipment and techniques designed to enhance the flexibility, ease of use, and scalability of mixing processes. From the precise addition of vitamins and antibiotics in animal feeds to the meticulous blending of Active Pharmaceutical Ingredients (APIs) with excipients in medications, the role of powder mixing is omnipresent.

The Evolution of Mixing Technology

Historically, powder mixing was a labor-intensive process, fraught with inefficiencies and inaccuracies. However, recent technological developments have revolutionized this field. Current mixing systems are not only more efficient but also capable of handling larger batch sizes and offer both batch-wise and continuous operations. The challenge for process engineers is not merely to mix but to create a uniform distribution of particles, thereby minimizing segregation and enhancing the quality of the final product.

The Battle Against Segregation

Segregation, or demixing, is a notorious adversary in the mixing process. It can occur at any stage, from mixing to transport, and even during storage. Engineers must contend with various forms of segregation, such as fluidization, sifting, and dusting. Each of these phenomena can disrupt the uniformity of a blend and compromise the quality of the end product. Fluidization, for instance, can cause lighter particles to rise and heavier ones to settle, leading to an inconsistent mix. Sifting and dusting further complicate the process by causing finer particles to concentrate in certain areas, undermining the objective of a homogenous blend.

Strategies for Preventing Segregation

Preventing segregation is paramount to the success of powder mixing. Research in this area focuses on understanding the conditions that lead to demixing and developing methods to counteract them. Process engineers employ various strategies, such as adjusting particle size distribution, optimizing mixer design, and carefully controlling the mixing environment, to combat segregation. Segregation studies are instrumental in this effort, providing a scientific basis for predicting and preventing demixing.

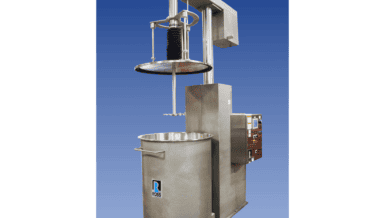

Insights into Mixer Selection

Mixer selection is a critical decision that can determine the success or failure of the mixing process. The outcome of segregation studies often informs this choice, indicating whether a low or high shear mixer is appropriate for a given blend. The selection is predicated on factors such as particle size, density, and the desired properties of the final product.

Challenges and Solutions in Powder Mixing

Despite the advancements in mixing technology, process engineers face a multitude of challenges. Achieving a uniform mix is a delicate balance that requires a deep understanding of material properties, mixer capabilities, and the interplay between different variables. Solutions to these challenges include the development of more advanced mixers, the use of computer simulations to predict mixing outcomes, and the ongoing research into the physical properties of powders.

The Future of Powder Mixing

Looking ahead, the field of powder mixing is poised for further innovation. The integration of artificial intelligence and machine learning into mixing processes promises to enhance efficiency and precision further. As industries continue to grow and evolve, the importance of effective powder mixing remains paramount. The process engineers who master this art will play a crucial role in shaping the quality of products across various sectors.

Conclusion

The complexity of mixing powders in an industrial setting cannot be overstated. Process engineers must navigate a labyrinth of variables to achieve the desired blend quality. The evolution of mixing technology has brought about significant improvements, but the challenges of segregation and mixer selection persist. Through continued research and technological innovation, the industry strives to overcome these obstacles, ensuring that the mixing of bulk solids remains a testament to the ingenuity and determination of engineers worldwide.