When your powder escapes, it has many implications for the hygiene and safety of your plant and is a drain on your plant’s cost effectiveness.

Whilst many process steps take place inside custom-designed pieces of equipment, the most problematic area for potential product loss and subsequent downtime is at the transition points between machinery.

The Problem of Product Loss

Product loss has been a long-standing issue for powder processing plants, but it has become even more important with the focus today on cost controls and sustainability in all areas of business. Any unnecessary waste in manufacturing plants needs to be minimised, both for the sake of profitability and a company’s social responsibility.

Powder loss often occurs wherever product moves from one part of a process to another but is a particular problem between pieces of equipment where movement is involved, such as into or out-of sieves and sisters.

Product transitions between these types of machinery are via a flexible connection of some sort and whether you call them a flex-connector, a sleeve, bellows or boot, they need to seal well and be durable to perform efficiently.

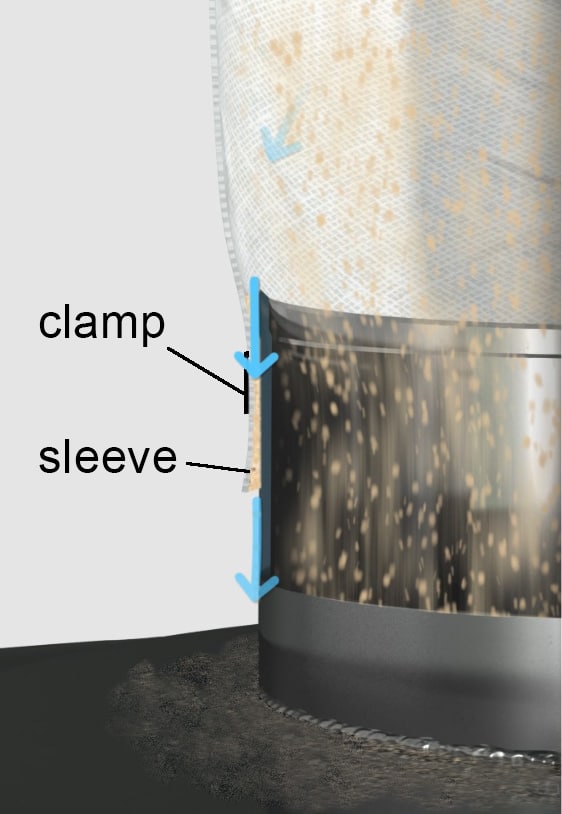

Historically, dry bulk-processing plants have used clamped flexible connector systems, which – despite the best efforts of maintenance staff – commonly experience powder leakage.

Why Clamped Connectors Leak

The fundamental issue for most clamped connectors is the fact that they are positioned on the outside of the pipes being connected, then fastened in place. This immediately creates an avenue for powder to escape through the gap created between the pipe and the sleeve – no matter how small it may seem.

Even when product doesn’t manage to escape out through gaps, it still tends to build up in the crevices that exist on the outside of the pipe, creating a contamination risk.

The addition of pressure into the mix increases the rate at which powder finds its way out of the connection and into the plant atmosphere. Of course, any powder escaping into the factory environment presents a serious explosion safety risk and needs to be taken seriously.

Movement often accelerates any leakage or failure issues with flexible connectors. Sharp edges of hose-clamps commonly rub on connector material, causing holes which then often tear during operation causing complete connector failure.

Downtime for clean-ups and connector replacements can be considerable.

As if the potential safety risks and downtime caused by product loss aren’t bad enough, any continuous leakage of product is pure waste, representing significant financial loss over time.

Keeping Your Product Inside Your Process

The purpose of a flexible connection is to safely, reliably and cleanly transport product between machinery whilst avoiding any transfer of movement from one piece of equipment to the other.

The simple fact is, most clamped flexible connectors struggle to perform this task and leakage and failure is common, especially where pressure or movement are involved.

That’s why industries from food to pharma to mineral processing are changing to the only flexible connector technology that fully addresses the drawbacks of the old-style connector systems used in the past.

The BFM® fitting has become a game-changer for powder processors. It features a unique, patented spigot and connector system that is designed to keep your product inside your process and make maintenance a breeze.

Zero Product Loss With BFM®’s Internal Seal

One of the most significant advantages of the BFM® fitting system is its ability to eliminate product loss during product transfer. Unlike traditional alternatives that use hose clamps and gaskets, the BFM® fitting employs an easy snap-in, snap-out mechanism that fits the connector on the inside of the pipe, creating a secure and dust-tight seal.

The innovative design means the internal surfaces are smooth with no possibility of leakage or product build-up. Even with movement like that on sifters, the BFM® fitting connector stays securely in place. If the process operates with positive pneumatic pressure in the system, this simply pushes the connector outward into the spigot, improving the seal.

The durability of the materials and quality construction of the BFM® fitting system ensures they will outperform clamped connectors in every aspect and will reduce product loss and maximise productivity.