With 30-years’ experience in product development and engineering solutions in the injection molding and mold making industries, Tom Houle, Director of LUMEX NA for Matsuura USA, is passionate about manufacturing solutions, operational excellence, and continuous improvement.

This year, one of his focuses was to improve the work environment by automating metal powder recovery at the Matsuura Machinery USA LUMEX Additive Manufacturing Center, a laboratory and demonstration facility inside Matsuura USA’s headquarters in St. Paul, Minnesota, where the company showcases its hybrid manufacturing technology, performs tests and produces billable parts on a one-off basis.

Beyond automating the metal recovery process at the demonstration facility, an equally important goal was the ability for Matsuura to provide its customers with a proven turnkey metal recovery system as auxiliary equipment for its LUMEX series of hybrid 3D printers.

The hybrid manufacturing technology combines advanced manufacturing techniques of selective laser metal sintering (SLS) with precision high speed machining (HSM) to produce a finished part that doesn’t require post machining.

This unique hybrid manufacturing machine supports the engineering and manufacture of highly complex integrated parts and molds in shapes and configurations that were once impossible using traditional milling methods.

During the unique hybrid manufacturing process, a thin layer of metal powder is distributed across the entire build platform, and laser fused, or sintered, to create the geometry of the part, leaving most of the powder outside the geometry available for reuse.

During the additive process, some tiny metal powder molecules outside of the build geometry also become fused; and, during the subtraction process of milling, miniscule metal chips deposit within the unused metal powder, both needing removal before reuse. This miniscule debris still looks like powder; however, in comparison to the finer powder, it is quite large.

With such an advanced manufacturing process that allows parts makers to reduce cycle times up to 45 percent, manually sieving the metal powder for reuse seemed counterintuitive to Houle.

Manual sieving “is a messy, tedious, and time-consuming job,” says Houle. “it was a bit like panning for gold, taking multiple hours to sieve just 10kg of material. Our machines use 160kg of material, so the process was daunting.”

In his effort to fully automate the sieving process, Houle evaluated six different suppliers of sieving equipment measuring willingness and ability to engineer a solution, ease of design process, breadth of offerings, price, and delivery.

Automated sieving systems utilize vacuum conveying to transfer material to sifting equipment.

“Since additive manufacturing is a relatively young industry,” Houle says, “few of the suppliers had experience working within sophisticated and regulated industries. Most had only worked with more traditional powders and processes.”

From the six suppliers, Houle says he selected VAC-U-MAX, because “their experience with conveying all types of media, and specific focus on metal recovery, allowed them to quickly understand our needs.”

Celebrating 65 years in business, Belleville, New Jersey-based VAC-U-MAX, a pioneer in vacuum pneumatic conveying, specializes in the design and manufacture of pneumatic systems and support equipment for the conveying, weighing, and batching of dry materials. With proven pre-engineered conveying solutions and industry expertise with over 10,000 powders, the company regularly designs custom solutions for manufacturers.

Metal powders used in AM are fine, heavy, dusty, and sometimes reactive, requiring specialized knowledge of material characteristics; however, Doan Pendleton, President at VAC-U-MAX says “metal recovery systems are fairly simple systems to us. It was a little more complicated with Matsuura because they wanted to weigh small amounts of the recovered powder into smaller containers for inventory control purposes and ergonomics and that required a little more engineering.”

Metal recovery systems use vacuum to extract powder directly from 3D printers, from dryer trays, or other containers, convey it to a vacuum receiver which discharges powder into a sieve, which then discharges good powder into a pail, drum or other intermediate bulk container for reuse—all within an inert environment.

The conveyor manufacturer has four levels of plug and play metal recovery systems all of which have standard inert gas purging capabilities for use when needed. Gas purging minimizes moisture and keeps reactive materials inert by limiting the oxygen concentration surrounding the powders as described by NFPA 69 and NFPA 484. Additionally, the vacuum conveyor equipment is static bonded and grounded, bolstering system safety by knocking out any static charge that may build up from the vacuum conveying process.

In metal recovery systems, the sieve is the heart of the system. The conveyor manufacturer standardly uses 63-micron screens for metal powder recovery which translates to 230 mesh, having 230 holes per linear inch.

With mesh that fine, the use of ultrasonics eliminates the risk of blinding the sieve and yields higher powder processing speeds.

Ultrasonics excite the wires in the screen, helping to distribute the material across the full diameter of the screen and pass the good material through screen. Without ultrasonics material builds up in the center of the screen, slowing the screening process.

According to Houle, the conveyor manufacturer “adjusted and controlled the ultrasonics and selected the screen size to match our process, our powders and the speed at which we were conveying powder,” he says. “What used to take an hour and a half, and require two operators, now only takes four minutes and one operator.”

In addition to engineering conveying system components to match Matsuura’s powders, the conveyor manufacturer worked with the hybrid machine manufacturer so it could reuse the original containers used to load media back into the hybrid AM printer.

The containers hold approximately 22 pounds of material making them manageable for workers to manipulate during the loading process, minimizing ergonomic hazards. Reusing the containers also allowed the hybrid manufacturer to reseal them with desiccant packs, reducing the frequency of drying cycles needed for hygroscopic metal powders that will absorb moisture from ambient air.

Maximizing sieve throughput and screen lifespan requires a metered feed of material into the sieve. Therefore, VAC-U-MAX implemented a level control that senses when the vacuum receiver is full. The system then stops the conveying cycle, opens a discharge valve that feeds into a vibratory tube which then meters the amount of powder discharged onto the screen deck. The reusable powder is collected in a dedicated pail and the sieved (i.e. waste) powder is directed into a separate vessel. The reusable powder sits on a floor scale that ties into the metal powder recovery system’s control panel.

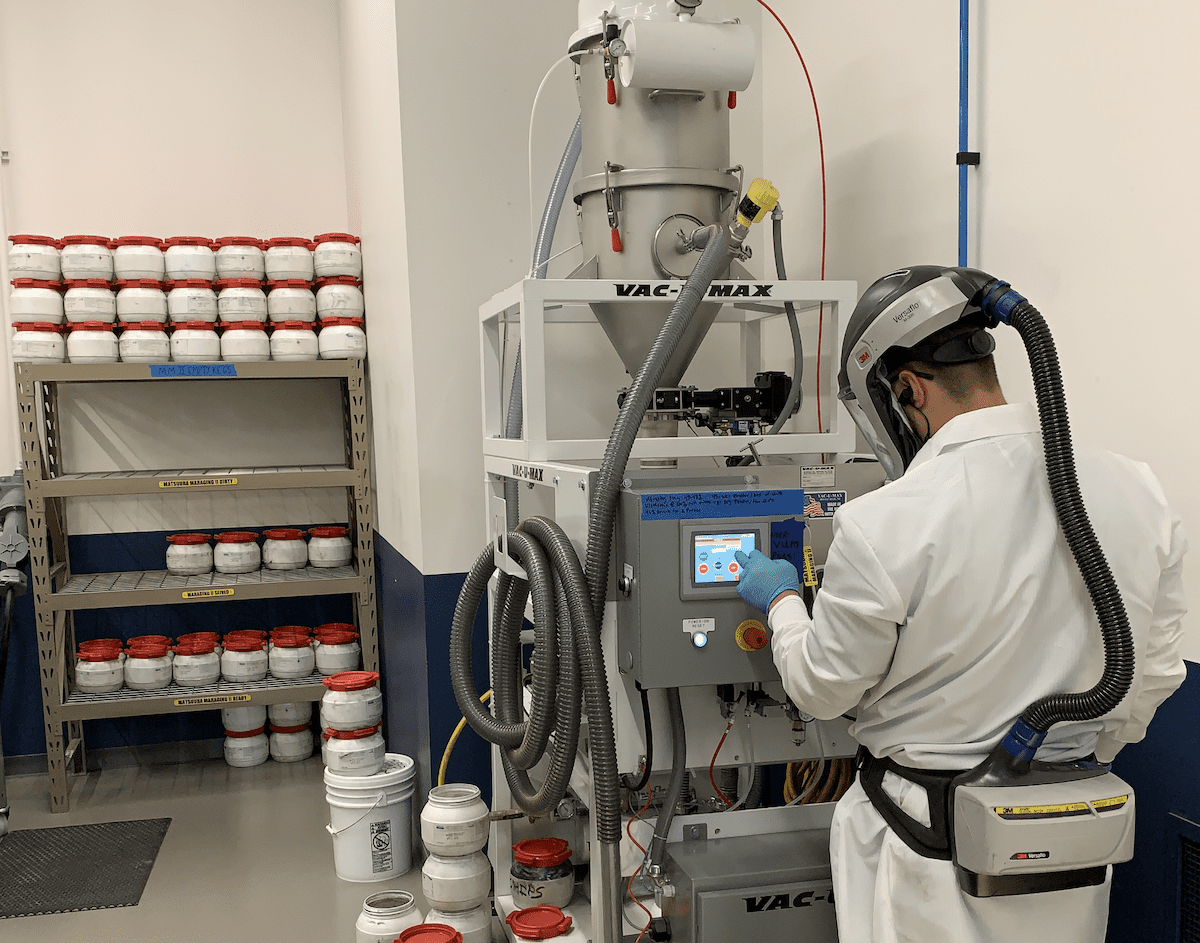

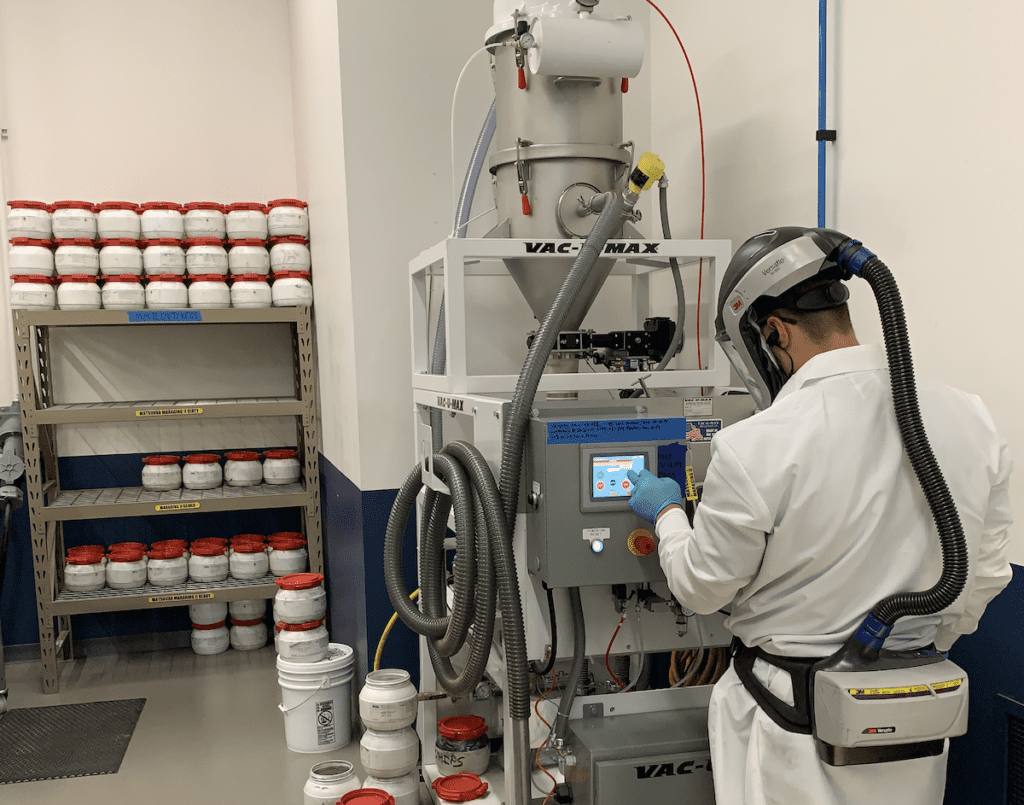

The touch screen control panel allows operators to manage everything from one place and operate major components separately when necessary, such as turning the sieve on and off, operating the sieve independently from the conveying system and pulsing the filters for cleaning.

Houle says, “the VAC-U-MAX system is a great auxiliary component to additive manufacturing. Because we are more efficiently removing impurities from the combined laser and milling process, we are able to reuse a higher percentage of our powder.”

“We contracted with VAC-U-MAX to provide a turnkey, fully automated, sieving system for use with our metal hybrid printer, and it works perfectly,” says Houle. “Any time we can provide a turnkey system with all of the necessary auxiliary equipment to our customers, it is of great benefit.”

To learn more about how VAC-U-MAX pneumatic conveying systems can improve efficiency, ergonomics, preserve product integrity, or reduce costs, write to them at 69 William Street, Belleville, NJ 07109; call 1-800-VAC-U-MAX (800) 822-8629 or (973) 759-4600; e-mail info@vac-u-max.com; or visit their website www.vac-u-max.com.

For more information on Matsuura’s LUMEX Technology, please visit: MatsuuraUSA.com.