HammerTek Corporation® – The inventor of the Smart Elbow® deflection elbow

The Smart Elbow® deflection elbow for pneumatic and slurry conveying systems virtually eliminates elbow wear, product degradation, plugging, surging, cross-contamination, noise, turbulence, etc.

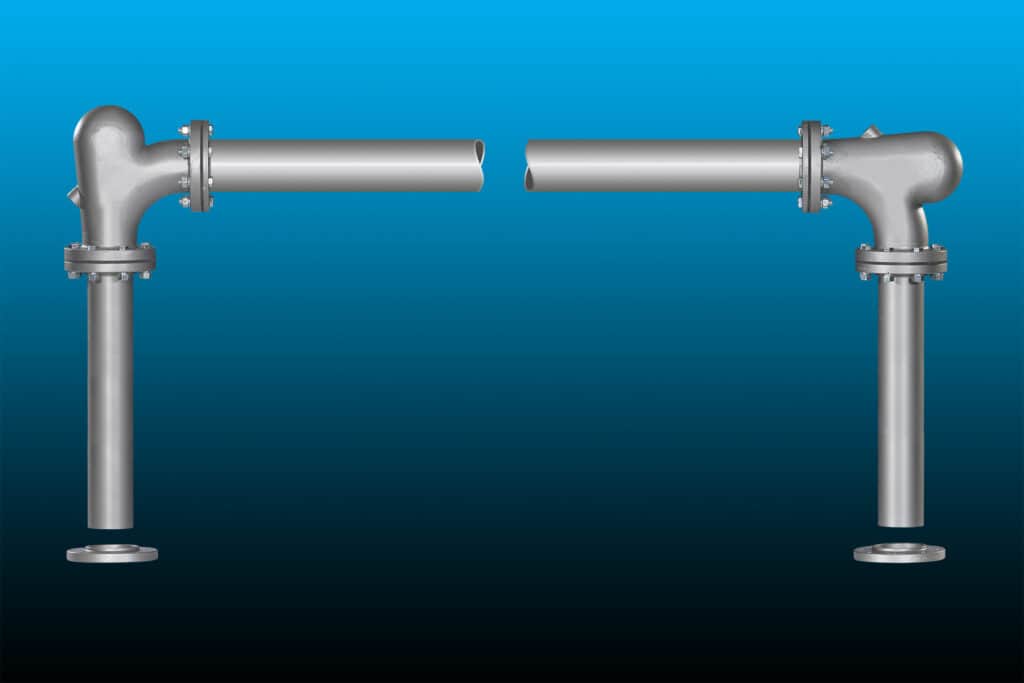

The Smart Elbow deflection elbow from HammerTek is the only elbow on the market to convey by creating a true deflection zone. Other elbows cause material to change direction either by filling a pocket so that conveyed material impacts the filled pocket, or by the conveyed material impacting the elbow and pipe walls. This impact causes elbow wear, product breakage, and the friction responsible for streamers, angel hair and snakeskins.

The Smart Elbow design causes materials to change direction by deflection, eliminating the impact zone – thereby eliminating elbow wear, friction, and product degradation.