Elcan Industries’ state-of-the-art Electromagnetic Separator Equipment has been a groundbreaking success with companies in the battery manufacturing industry. Elcan’s electromagnetic separator is not only setting new standards in the industry but is also redefining the benchmarks for efficiency and versatility.

A Class Apart: Class II, Div II, UL-Rated Electromagnetic Separator

At the heart of our innovation is the Electromagnetic separator, which proudly boasts a Class II, Div II UL Rating. This distinction sets it apart from many other separators in the market, emphasizing its superior safety and reliability standards.

Up to 19,500 GAUSS. Versatility. Customization.

Our Electromagnetic Separator can achieve up to an unparalleled 19,500 GAUSS, currently making it the strongest Electromagnet equipment in the modern world. Whether dealing with wet or dry materials, this separator is optimized for both, ensuring efficient separation even when moisture is a concern.

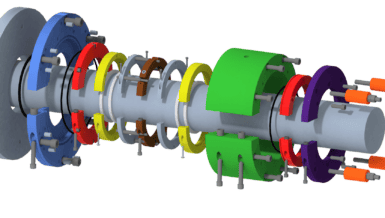

Understanding the diverse needs of various applications, Elcan Industries’ electromagnet is designed with user-friendly interfaces and features, simplifying the operation and the ability to switch between multiple types of magnetic screens. These can be easily changed based on the application’s specific requirements, offering unmatched flexibility to our clients.

A Boom for the Battery Manufacturing Industry

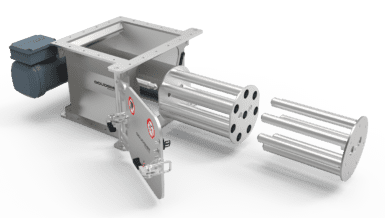

With the recent surge in demand for battery materials, our Electromagnetic Separator has found significant use cases in the battery manufacturing industry because of its compact footprint, its ability to be combined with our advanced sieving technology, the Hi-Sifter, and the ability to separate even the finest particles of under 0.01mm ensuring the highest purity of materials, a critical factor in battery production.

Additional Features for Enhanced Efficiency

Effective Iron Separation: This is achieved by directing the magnetic flux to the unit’s center, ensuring even the finest iron particles are separated.

Vibration for Improved Flow Rate: Including vibration ensures effective iron removal, enhancing the screen flow rate for smooth material flow.

No Magnetic Leakage: Our design ensures that the magnetic force is fully harnessed for the separation process, guaranteeing maximum efficiency.

Wide Range of Products: Apart from the flagship CG electromagnetic separator, Elcan Industries offers a variety of models, including the CGX, ensuring that customers have many options tailored to their specific needs.