For the production of batteries, the individual metallic raw materials such as, amongst others lithium, cobalt, graphite, nickel and manganese must be dedusted, fractionated, and/or control screened and therefore qualified for further production.

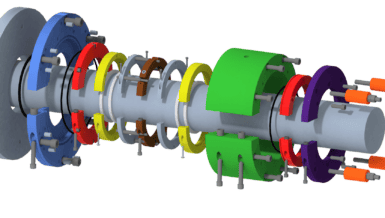

For screening these raw materials, the GKM vibrating tumbler screening machine KTS-VS is the ideal solution.

This machine can be manufactured according to the customer’s requirements with various surface-contacting stainless steels and surface qualities. The machine is certified according to the latest standards, such as ATEX. Various features as quick-clamps facilitate and accelerate the handling and maintenance of the machine enormously. Furthermore, the machine can be equipped with various screen cleaning systems to ensure a smooth continuous production. According to customer requirements, the machine can be equipped with several screen decks for different fractions, the cut-points usually being in a range between 0.032 and 1.0 mm. Here, a very efficient, emission-free and almost noiseless ultrasonic cleaning device is used.

In order to protect the user and the environment, these machines are absolutely dust-tight and grant easy, quick maintenance thanks to the facilitated access. Thus, pneumatic as well as manual cover lifting systems can be permanently installed on the machine.

In the recycling process, batteries are first crushed and, with the help of the GKM tumbler screening machine KTS, highly efficiently fractionated into individual components, such as foils, outer casings and black mass (consisting of foil, Al, Cu, small amounts of Fe). In most cases, the required cut-points are between 0.3 and 6.0 mm.