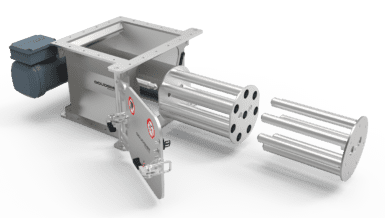

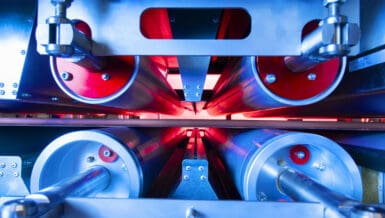

The magnetic filter produced according to EHEDG guidelines is composed of Neodymium magnets that ensure effective separation of very small iron particles from 30μm, weakly magnetic particles and even iron dust from sticky substances such as chocolate. The hygienic filter can be seen on the Powtech in Nuremberg, position 3-634. In the new design, the housing is not welded but made of one piece -RVS 316-.

The new design prevents the heated liquid, e.g. water, from entering the product channel. This water flows through the outer wall of the filter and keeps the chocolate liquid. In the fully modular design, a standard filter vessel of choice can be an ISO or a DIN pipe. This makes the filter easy to integrate into existing installations and also suitable for all couplings. The system fully meets the highest possible requirements within the food industry, such as HACCP and EHEDG.

Modular design

An advantage of the modular design is the ability to easily apply the desired options. For example, an extra powerful magnetic core that increases the magnetic value to 11,000 gauss. Cleaning can easily take place semi-automatically with the help of a tool. The optional “Lock out, Tag out” or LoTo safety system ensures that the magnet will only return to production if the magnet is properly replaced after cleaning. A detection sensor to be applied as desired continuously checks whether a magnetic field is present in the product channel.

The magnetic filter is used in tubes and/or pipelines in the food industry, where it performs deferrization of products conveyed under pressure. Even the smallest iron particles can be filtered out of sticky substances, such as chocolate.

Visit Goudsmit Magnetics during Powtech, stand 3-634