Dairy products are very sensitive and require strict hygiene practices, and it is only appropriate that these requirements are taken very seriously. In this article, we look at the problems to take into consideration when choosing a magnetic separator for dairy manufacturing applications, the types of magnets applicable to different dairy processing applications, and how you can ensure that your magnets are effective and meet the industry standards.

Let’s get straight to the point – what are the problems that you should look out for when selecting magnetic separation equipment for dairy applications?

- Blockages – Fixed magnets can restrict flow.

- Product Stream Coverage – Limited coverage can leave some product only partially protected. This means that if a magnet is not installed correctly in the process or the magnet has a poor design, it can result in ineffective metal fragment control, and contaminants can remain in the final product.

- Retention Efficiency – contaminants can escape the magnet and be re-introduced to the finished product. This can be caused due to a magnet’s design being inadequate for a certain type of processing line, poor magnet strength, and other.

- Cleaning and Maintenance – Biohazards can be introduced via dead zones or unsuitable designs. For example, the use of magnet sleeves for easy cleaning – product can remain in the sleeves and lead to build up of bacteria. Additionally, using the sleeves can result in re-contamination of the product, as metal fragments can fall back into the product stream during cleaning.

The primary duty of magnetic separators is extracting magnetic fines contamination from the process. Effective separation is critical!

Powder density and flow-ability can greatly influence separation performance in dairy applications, depending on the magnet layout – in some cases it can prohibit effective separation.

The above-listed problems need to be taken into consideration prior to selecting a magnetic separator. Now, let’s have a look at the different types of magnets for different dairy processing applications, and both the advantages and disadvantages of the various magnets.

Rotary Powder Separator

The Rotary Grate Magnet should only be used for powders that are at high risk of blockage and would not flow through a fixed magnet properly.

Some advantages of Rotary Magnet Designs include no blockages due to constant agitation by the magnet, as well as excellent product stream coverage due to multiple contacts.

Some disadvantages include a higher risk of contaminants escaping the magnet due to constant agitation and erratic flow, and that although the magnet has a sealed design, there is exposure to atmosphere during cleaning.

The Magnattack® Rotary Grate Magnet can be supplied with a Rapidclean® Cleaning Tool for easy and effective cleaning.

Rapidclean® Fixed Grate Magnet Design

This magnetic separator is only suited to free-flowing dairy powders. The product flow can be optimised with custom magnet configuration and vibratory flow aides. It is important to perform testing and take extra care when specifying magnet size and volume area for sticky powders.

This magnet is fully customisable, which can result in excellent product coverage. Due to this being a static grate magnet design, the contaminants are safely retained on the magnetic bars.

A disadvantage is that although the magnet has a sealed design, it allows for exposure to atmosphere during cleaning.

The Magnattack® Rapidclean® Grate Magnet can be supplied with a Rapidclean® Cleaning Tool for easy and effective cleaning. This magnet is suitable for most powders.

Mag-Ram® Automatic Self-Cleaning Grate Magnet

This self-cleaning grate magnet has a very versatile design and is successful in all types of dairy powders, including lactose powders. The Mag-Ram® is low maintenance, USDA-Accepted and sanitary, making it a great choice for dairy powder applications.

The self-cleaning function releases lumps and clears excess build-up, and the air-tight design eliminates ingress and preservation against external atmosphere, even during cleaning!

This magnetic separator has static, large diameter magnets, which results in safe retention of contaminants. Larger diameter elements over multiple rows are required to improve coverage.

The Mag-Ram® can be programmed to clean before, during, or after production runs and the automatic cleaning options can suit each application, product, and tonnage rates.

Spherical Pneumatic Transfer Magnet

The Spherical Magnet is an excellent choice for high-velocity pneumatic lines, as it minimizes product particle breakdown and prevents blockage of product.

The aerodynamic design of this magnetic separator allows the magnet to collect AND retain contaminants in pneumatic powder applications, without experiencing bulk density changes and pressure loss.

The Spherical Magnet is very powerful and has high gauss strength, which is a huge advantage when comparing it to conventional bullet-type or plate magnet designs, which typically don’t exceed 7-8,000 gauss and are not adequate for final product security applications. It is also more sanitary, smaller, lighter, and will give you a higher assurance of effective foreign metal fragment control.

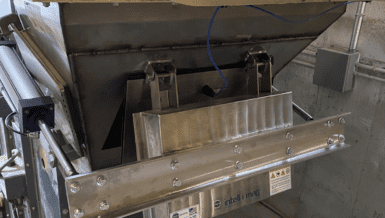

Emulsion & Slurry Pipeline Separator

The Emulsion & Slurry Pipeline Separator is a great choice for think, viscous liquid slurries and emulsion lines. This magnetic separator is USDA-Accepted and sanitary and can be installed in horizontal, sloping, and vertical pipelines, sized 1”-6” (25mm-152mm).

This magnetic separator features powerful, high-intensity Acutex® Probe Magnets. The probes have a distinctive lachrymiform (or teardrop) shape, which allows for very smooth transition of viscous products to move around the magnet with minimum resistance to flow. Maximum product to magnet coverage is achieved without causing leaks, blockages, and pressure problems.

The peak (or V-section) of the probe is faced toward the oncoming product stream, ensuring that collected magnetic fragments are washed to the back of the probe and safely retained until cleaning operations are underway. This feature greatly reduces the risk of recontamination caused by the impact of the product flow dislodging the collected fragments and reintroducing them back into the product stream.