Materialise, a global company based in Belgium, specializes in rapid prototyping and additive manufacturing across various sectors like healthcare, automotive, aerospace, and consumer goods. With one of the world’s largest 3D printing facilities, they meet strict production deadlines while offering flexibility.

In Bremen, Germany, Materialise’s competence center focuses on metal 3D printing, uniting over 100 specialists from R&D, software, and partners. They excel in prototyping and additive manufacturing, utilizing EOS M280 and SLM printers with 316L stainless steel powder.

Previously, Materialise manually handled powder reclaim processes, leading to productivity and safety challenges. As demand grew, more 3D printers were added, increasing the volume of powder to be reclaimed. However, their recovery process couldn’t scale up with the rise in additive manufacturing, necessitating a focus on operator safety.

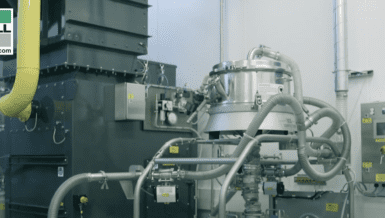

The introduction of the Russell AMPro® Sieve Station has automated Materialise’s operations by supporting multiple 3D printers, enhancing production capacity. It reclaims powder from up to four printers during peak production, streamlining the sieving process for faster results. This quality sieving minimizes powder loss due to oversized particles and improves operator safety.

To speak to an experienced sales engineer to improve your productivity, contact Russell Finex today.