Since 2015, NFW has developed a material platform to transform natural, biobased inputs into high-performance, plastic-free materials. NFW’s patented plant-based leather alternative, MIRUM® offers businesses an eco-friendly substitute for synthetic or fossil-based textiles, without compromising on quality or performance. To date, the product has gained attention from BMW, Ralph Lauren, Stella McCartney and Levi’s, among others.

IPCO innovates, manufactures and installs equipment and steel belts that enable high-volume industrial processing. The company is now becoming a preferred business partner to companies seeking to scale up the production of new materials which accelerate the green transformation.

“We were looking for a technology enabling large-scale production, to meet the demand we see in the market. Having evaluated different options, we see IPCO and their double-belt press solution being the optimal way forward,” comments NFW CEO Luke Haverhals.

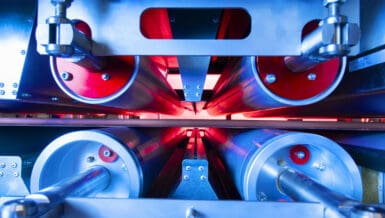

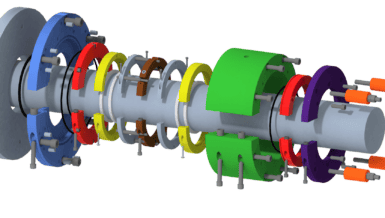

IPCO’s double-belt press leverages IPCO’s unique technology platform and steel belt modules. After several months of engineering and testing, IPCO’s double-belt press went live at NFW’s facility in late May 2023 and has now started to produce 1.6 meter wide rolls of MIRUM®.

“IPCO’s double-belt press will enable us to scale up and meet the growing demand for sustainable materials. The machine is performing well, and we are delighted with the support from IPCO’s service center,” comments Luke Haverhals.

IPCO and NFW have also agreed to enter into a partnership agreement in which IPCO will invest in NFW to support and accelerate the scale up of MIRUM® production as a sustainable leather alternative for the future. NFW will use the investment to further expand production capacity, while also exploring new sustainable applications and materials.

“By investing in NFW’s future, we’re showing IPCO’s strong commitment to NFW’s scale-up and future success, and we can secure long-term opportunities in a growing and sustainable field. We see tremendous growth potential in segments and application areas linked to the green transformation,” comments IPCO’s CEO Robert Hermans.

“The strategic partnership between IPCO and NFW is a good example of how a traditional industrial company with deep, long-standing knowledge within technologies can enable large-scale production of materials driving the green transition. This partnership is fully in line with the greater purpose of IPCO’s owners, FAM (a holding company owned by Wallenberg Investment AB), which has a passion for long-term development, innovation and social responsibility driving the transition into solutions sustainable for the future,” continues Robert Hermans.