Grinding and classifying are important process steps in the industrial production of various products concerning the food and luxury food sector as well as in chemical, pharmaceutical and general bulk materials industries.This applies not only on a production scale, but also on a laboratory scale, for the development of new products and the search for new properties, as well as for increasing efficiency and reducing production costs. A wide-field, that is becoming increasingly complex and demanding as technical development progresses. Nevertheless, modern laboratories should always be capable of handling different process steps and requirements in an efficient and repeatable way.

Today’s laboratory plants usually concentrate on individual machines and their respective tasks. For example, in grinding with subsequent particle separation, the test product must be ground first, then collected and transported to a second machine where the classification process takes place. This is often a dust- and labor-intensive process that can easily lead to product contamination and even product loss. In addition to the space required for several machines, the explosion risks at various points, for example, must also be taken into account.

The situation becomes even more problematic when the particle fineness in comminution tasks is to be varied over such a wide range that the standard impact milling technology does not provide enough energy for the desired finenesses or even a controlled maximum particle size cannot be achieved – which is, however, required for many applications. The requirement for a narrow particle size distribution in turn means that a certain proportion of coarse or fine product has to be separated after grinding. If this is in the range below 100 μm, only air classification can be used here.

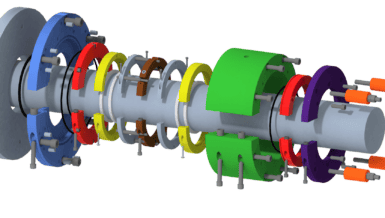

Especially for such tasks, NETZSCH has taken the well-known LabCompact system as a basis and constructed the new LabPilot system on it. In addition to a facelift, which brought not only optical changes, but also further advantages in terms of user-friendliness, cleaning and maintenance, LabPilot has been expanded to include additional grinding technologies. Now, in addition to the jet and classifier mills available so far, the fine impact mill Condux® and the dry agitator bead mill SpheRho® can also be used. This expands the possibilities for comminution in laboratories to include many more areas of application.

For example, the Condux® fine impact mill can be used to process a wide variety of products up to a Mohs hardness of 3 – 3.5. Depending on the product properties and comminution task, the laboratory mill is equipped with different grinding tools (pin discs, blast rotor, wing beater) and stators. It thus flexibly covers a wide range of applications and is the ideal solution for initial feasibility studies and the production of small production quantities. Due to its operating mode and stress characteristics, the dry agitator bead mill SpheRho® achieves very high finenesses, combined with high throughput rates at low specific energy consumption. The main field of application is real comminution of various raw materials with typical product finenesses d50 in the range of 2 μm to 70 μm. The continuously operating dry agitator bead mill can be used both in individual passages without classifier and in a grinding/classifying circuit.

In addition to the systems mentioned, various other mills, such as jet and classifier mills as well as fine and ultra-fine classifiers, can be used with the NETZSCH LabPilot with only one installation by means of short adjustments and coordinated with the respective process gas quantity. With appropriate laboratory machines, the proven technology can also be used for the development of new products or for the production of small quantities on a laboratory scale. NETZSCH LabPilot offers maximum flexibility through the possible use of different mill types with subsequent classification stage in a closed system, including throughput mode. This avoids product losses, offers considerable facilitation/time savings and enables quick tests with different products. Easy accessibility and simple cleaning as well as the compact design make NETZSCH LabPilot an indispensable system in any particle technology laboratory environment.