The company switched from a hammer mill to a Munson SCC Screen Classifying Cutter to accurately reduce dates into granules and powders within narrow size ranges.

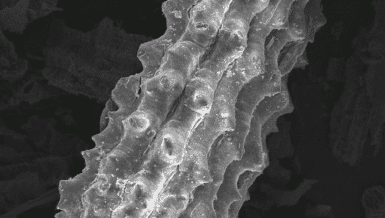

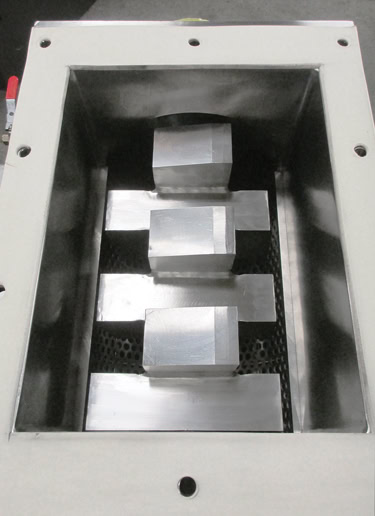

Harvested dates are dried and cooled, then loaded onto a conveyor, which feeds the dates into the throat of the machine. Unlike a hammer mill, where a series of hammers strike and break the material until it passes through a bed screen, the Screen Classifying Cutter employs solid stainless steel cutter blocks that are welded in a staggered array, with a machined cutting edge that can be re-sharpened.

A variable speed motor allows the plant to run the cutter at 1,500 rpm to produce particles down to 1/16 inch (or 1.6 millimeter)—or at 1,200 rpm for particles down to 3/16 inch (or 4.8 millimeter), according to customer requirements.

The Cutter processes about one ton of dates per hour, eight times faster than the hammer mill.

According to the company, the Screen Classifying Cutter has not required parts or maintenance in four years of operation, and has fewer moving parts than the hammer mill.