Thus being able to predict a particle’s future characteristics and its interactions. In short, more control over the production and handling process. For example, porosity makes the particle less dense and lighter, sieving shakes it all up, and the impacts and abrasions could reduce its size and shape, losing some of its surface areas in the process, changing its characteristics, and maybe affecting its eventual sedimentation process. Added to that the particle is probed and analyzed, using non-damaging Pycnometry or Coulter principle methods, and is looked at under a microscope and image analyzer. These are just a few of the many interactions the particle will face, on its journey to becoming a part of our society whether as a food product, health product or part of technology. As you can imagine particle processing and analysis are essential in our growing industries and have a great and exciting journey ahead.

Powder particles are of paramount importance when it comes to manufacturing whether the process starts at the raw materials-, intermediates- or the final products stage powders contribute to approximately 80% of the industrial processes of all manufactured goods and materials and go through a wide array of processes, quality controls, testing, and analysis to realize and maintain the desired product usability.

In the chemical industries such as pharmaceuticals, paints. coatings of metal components, catalysts, pigments, batteries, and additives. 75% of the semi-finished products are in powder or granular form and in many cases unwittingly these particles and powders catalyze the performance of a vast array of everyday products.

Powder characterization

Manipulating the character, the form, and functionality of the powders that are vital and essential materials in our respective industries helps to create better end products. Technology, its designers, and operators need to adapt, understand and work diligently together to improve our social goals of sustainability of the environment, and economic and the social dimension of our industrial production systems. This will drive the growth and progress in every sector of the industry from research and development, to design, and fabrication of high-quality products and storage in an already exponentially growing technological world.

We (Delft Solids Solutions) with our focus on the future and advancements in nanotechnology strive to be a part of that growth and development and we understand that together sharing knowledge and improving production solutions will help the industries move forward toward evolving sustainability. Researching and working on evolving the understanding of powder characterization is fundamental in achieving the aforementioned. Powder processing is seemingly complicated due to an array of different variables that affect the particle characterization such as flowability, particle shape, size, surface roughness, porosity, electrostatic charge, environ-mental conditions, and the medium used to convey or store all affect the end product.Having like-minded people from all fields in the particle science and processing industries come together to discuss sustainability and share ideas and technologies greatly benefits the industry and economy as a whole.

Powder technology processing and the road ahead

The particle we imagined at the beginning of this article is an individual entity and has its own defined size, shape, porosity, etc. basically its own characteristic. But as soon as these particles come together they are bulk assemblies and have moisture air and possible contaminants. These added complexities affect the properties of the powders with their specific characteristics and behaviors which with present technology is still difficult to predict.

Particle size reduction and micronization technologies such as nanonization are still evolving due to many industries showing inadequate aqueous solvability of their powders for their respective uses.

For example, active pharmaceutical ingredients need to be stabilized in polymeric stabilizers or surfactants to be of use. To obtain these nanoparticle ingredients several techniques are being used such as milling of the solids which is still the most important and successful method using high shear forces resulting in particle attrition.

Other methods in use, utilize chemical reactions like polymerization to produce nanoparticles or advanced evaporative precipitation into an aqueous Solution with organic solvents (solvent/ antisolvent) or supercritical fluid technologies or High-pressure homogenization. Hence research needs new ideas to expand on the existing ones.

The relevance of particle characteristics and research

According to recent surveys, the particle science industry related to analysis and research and development is continuously growing and is expected to reach 600 million USD by 2030. This shows that there is a great need and desire for innovation and future market growth in the pharmaceutical-, food/ feed-, and chemical industry segments. This is partly due to the drive towards constant developments of nanotechnology which is gaining more and more traction around the world. Nanoparticle tracking analysis, laser diffraction technologies, testing, and analysis are in demand partly because of stricter government regulations concerning food safety and in related industry segments such as biotech and biopharma.

Additionally, mandatory regulations of government guidelines on product quality, improved production standards, pollution, industry best practices, sustainability, and the growing government support for nanotechnologies all play a fundamental role in working together, sharing technology, education and research. The industry processes and production need to adapt to the exponential growth of technological advancements in quantum computing, nanotechnology, and artificial intelligence which will play a pivotal role in how we deal with the economy, industrial production, and the sustainability of the planet and future technologies.

Three days of practical courses

Amongst other specialties, the core of what Delft Solids Solutions does is a focus on particle science-based technological approaches in helping to understand, advise, assist in resolving issues as well as participate in the advances of the future of nano-particles fields and the techniques that will revolutionize the powder industries for decades to come.

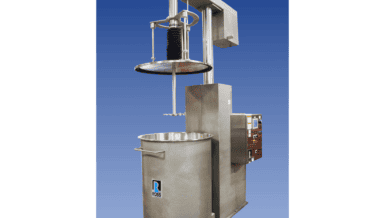

Because we believe the sharing of knowledge is imperative to grow, we, on Tuesday the 8th of November and Wednesday the 9th, will organise the Particle Size Characterisation course 2022 edition. We will offer insights into current techniques and best practices. During the course, we’ll share our lab and testing facility to put theory into practice. discuss the pros and cons of different techniques available and highlight what is possible in a current industry setting as well as what will be possible in the near future, with present technology and the advancements in nanotechnology in solids liquids and gaseous forms. We encourage a lively discussion of bright minds sharing information and knowledge from their practical experience.

The second course is the Porosity and Surface Area Characterization course 2022 and will be held on the 10th of November. This course partly builds on the information given in the Particle Size Characterization course but can sureloy be followed as a stand-alone one-day course. We though recommend doing them back to back with all the information is fresh in mind.