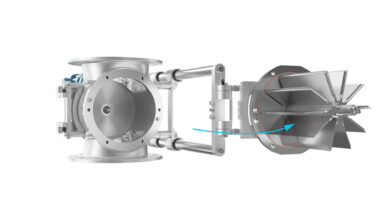

Devised to promote maximum line uptime and minimize the need for service calls, the Gericke rotary valves enable a single maintenance technician to replace worn slotted collars, shaft sleeves, end discs, body liners, and replaceable blades quickly using common hand tools. The entire process from disassembly and wear parts replacement to reassembly, resetting the clearances, and return to service may be performed in a matter of hours.

Frequently specified for abrasive materials such as cement, granite dust, silica sand, quartz, and other powders that cause extreme wear under normal operating conditions, the Extra Heavy Duty Series rotary airlock valves are manufactured in a choice of cast iron, carbon steel or SG ductile iron with optional chrome- or ceramic-coated body liners for extra protection against premature wear. The EHDM Series valves are available in a wide range of standard sizes and in custom sizes to suit any bulk solids processing installation.

Designed, manufactured, tested and inspected at the company’s headquarters, the Extra Heavy Duty rotary valves and replaceable parts are delivered ready for installation with a one-year warranty included as standard. Testing is offered live at the company’s New Jersey test center or via online livestream.