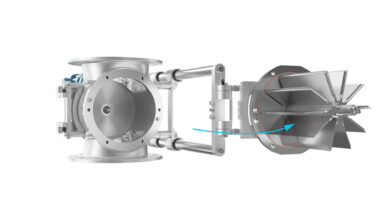

Rotary feeders play a fundamental role in modulating bulk material flow, a process that necessitates uninterrupted operations. Unfortunately, various challenges related to rotary feeders may arise during operations and these may include the following; (i) abnormal vibrations caused by rotor shaft misalignment, (ii) bearing damage due to overheating, (iii) premature shaft seals damage caused by contamination due to air purges malfunction, (iv) insufficient material throughput due to excessive air leakage at inlet and outlet ports of the feeder, (v) jamming due to trapped material leading to feeder shuddering which can eventually cause the drive chain to hop or affect the rotor speed, and (vi) noisy operation caused by higher bulk material temperature than originally expected, thus, resulting into rotor expansion. The normal rotor rotation speed gets affected in the case where the rotor blades come into contact with the feeder housing. Because machine checks are manually performed in most industries, the aforementioned rotary feeder challenges may not be identified early enough. This can result in unplanned machine downtime, increased maintenance costs, reduced machine health and performance, minimised machine lifespan, as well as reduced production output.

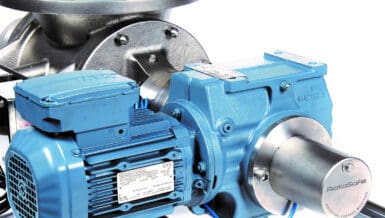

With industry 4.0 improving operational efficiencies through automation and other key Industrial Internet of Things technologies, Polimak provides smart rotary feeders that help process and manufacturing industries reduce unplanned downtime and improve the overall performance of production lines. Polimak combines process industry know-how with its expertise in software technology to provide quality smart rotary feeders. Our rotary feeder (typically utilised in process lines under a head of bulk materials and efficiently modulates material flow between two pieces of equipment) has our IoT solution platform (Politrace) that combines process conditioning, machine health and inventory monitoring, and computerized maintenance management technologies integrated into it. The feeder is fitted with a sensor system that is capable of measuring various operational unit parameters such as temperature and vibration of the feeder’s body, rotor speed, power consumption, air pressure at inlet and outlet ports, bearing temperature, air pressure at air purges, and safety protector cover detection as the feeder operates. In other words, the sensors are able to collect real-time data on the performance and condition of the rotary feeder. This provides early warning of potential rotary feeder challenges, thereby allowing personnel to take the necessary action before breakdown occurs. Polimak smart rotary feeder provides the following benefits:

- Minimised equipment unplanned downtime.

- Sufficient material throughput.

- Reduced costs.

- Improved production line performance.

- Real-time data observation.

- Predictive maintenance.

- Receive notifications for any performance abnormality

Polimak’s Internet of Things solution isn’t only compatible with rotary feeders, it can be fully integrated into other operating machines throughout process lines. The collaboration of manufacturing systems/machines with our IoT solution creates systems/machines that communicate data in real time.