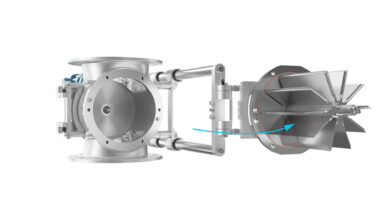

USDA-certified rotary valves from process equipment manufacturer Gericke, now feature the company’s proprietary RotaSafe(TM) detection system as standard. Developed to prevent fine metal particulates from contaminating food, dairy, and other products, the RotaSafe detection system automatically detects metal-to-metal contact between the rotor and valve housing and, in the event of detection, instantly shuts down power to the drive motor before serious damage can occur. The potential for product and process contamination, and for wear to the rotary valve components is virtually eliminated.

Proven in operation on the company’s standard duty rotary valves, the RotaSafe system may alert operators to excessive temperatures, imminent bearing failure, excessive load on the rotor, and other conditions that may lead to a detection event. The novel approach applies an additional level of hygienic protection to the Gericke HDMF dairy valves for sanitary processing. The rotary airlock valves also include stainless steel construction with polished internals and externals as standard.

The Gericke HDMF RotaSafe valves earned the USDA certification for complying with USDA Guidelines for the Sanitary Design and Fabrication of Dairy Processing Equipment. The valves may be tested at the company’s New Jersey test center and monitored in person or via online livestream.