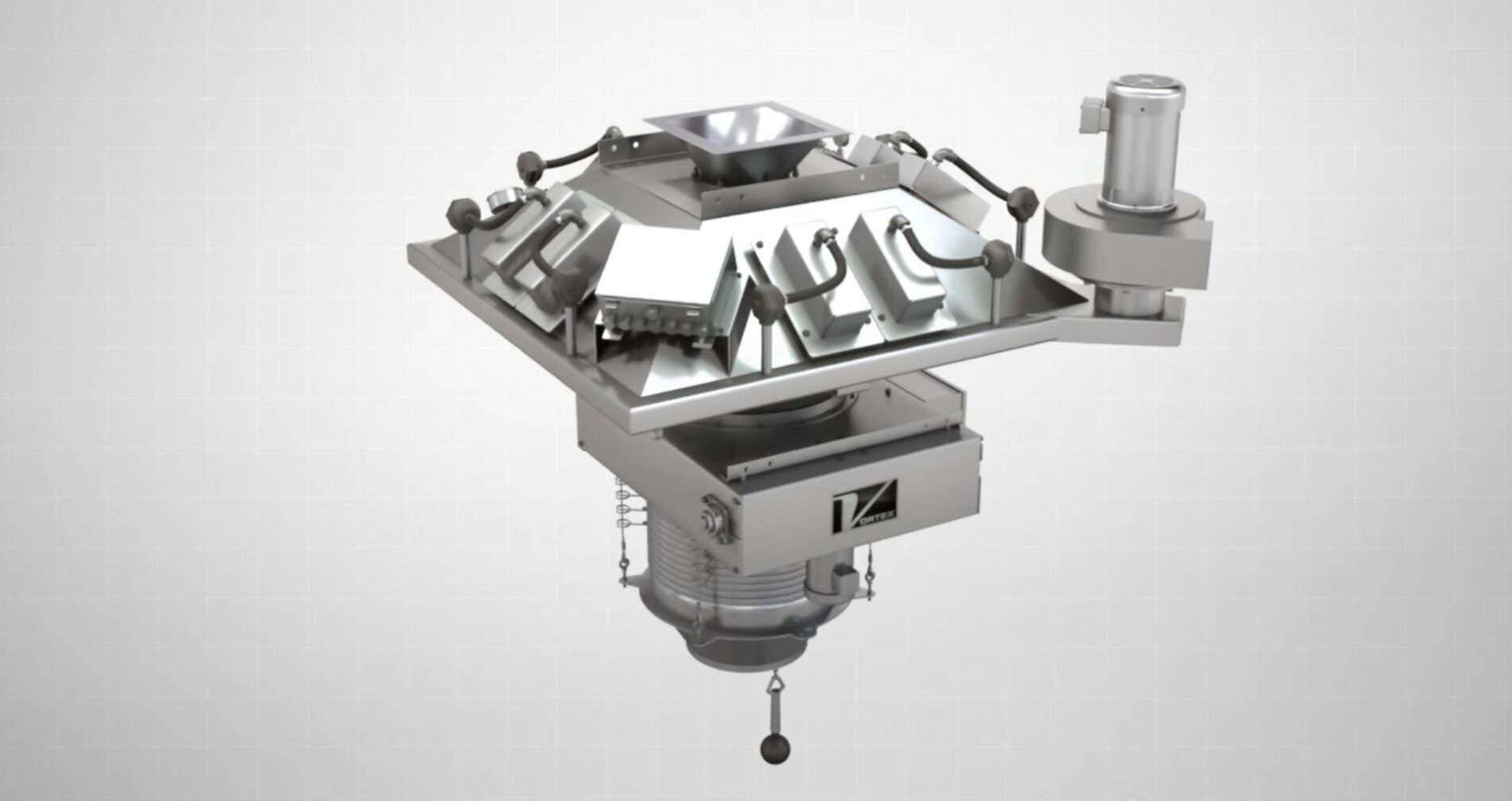

The Pivoting Chute Diverter operates by utilizing a pivoting chute mechanism that can be actuated to direct the flow of material towards one of two or three discharge outlets. This mechanism allows for smooth, uninterrupted flow with minimal material degradation, ensuring consistent product quality. One of the key features of the Vortex Pivoting Chute Diverter is its replaceable wetted parts, which include the actuator, pivoting chute, inlet chute, wear and containment bar, and abrasion-resistant liners. These components can be accessed in-line, allowing for easy maintenance and replacement without necessitating the removal of the entire diverter from the process line. This design significantly reduces downtime and increases cost-effectiveness, as only the worn parts need to be replaced. Another notable feature of the Pivoting Chute Diverter is its removable access panel, which allows for in-line inspection and maintenance. This is particularly beneficial in abrasive applications where frequent interior access is required for wear part maintenance.

Additionally, the Pivoting Chute Diverter is compatible with Vortex’s various material flow control assemblies, enabling total flow control towards a single destination or split flow towards two destinations. For larger valve sizes, the diverter can be modified to accommodate optional chute removal assist rods, making it easier to handle heavy chutes during inspection, maintenance, or replacement.

In summary, the Vortex Pivoting Chute Diverter is a versatile and robust solution for the efficient handling of heavy-duty and abrasive dry bulk solid materials in gravity flow applications. Its unique features, such as replaceable wetted parts and removable access panel, ensure ease of maintenance and longevity, making it a cost-effective and reliable choice for industries requiring precise material handling solutions.