Designed to reduce DIN rail space, it is powered from 10 to 28V DC and has 4 relay outputs, 3 digital inputs and transmission in all main industrial communication standards, making it ideal for easy connection to PLC, PC and remote systems.

The SWIFT V is usually configured on-site or remotely, using PC software, and also has a small pushbutton panel under the front faceplate for manual configuration.

It stands out for its high reading speed, at 2.400 weight readings per second, and its high ADC resolution of 24 bits, with 16 million internal divisions and 500 thousand external divisions.

It incorporates RS-232 and RS-485 communications (ModBus RTU and ASCII) and optionally 4/20mA, 0/10 V, Profinet or Ethernet/IP.

Applications

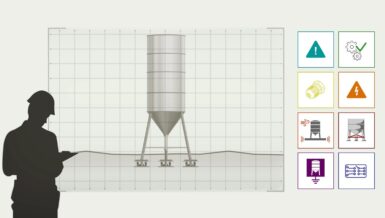

The SWIFT V is ideal for installation in industrial applications with the need to optimize DIN rail space. Therefore, it can be installed in:

- Weighing and Level Measurement in

- Tanks & Silos.

- Filling and Dosing Machines.

- Check-Weigher Scales.

- Animal Weighing Scales.

- Test Machinery.

- High Speed Dynamic Sorting Scales.

- Multihead Scales.

- PC/PLC Weight Transmision.

- Multiple Weight Indicators in the same Bus.

- Crane overload control.

The new SWIFT V is available in 4 versions, which are detailed below, together with their corresponding floor plan:

| VERSION | COMMUNICATIONS |

| 89480: SWIFT V RS+ANALOG | RS-232/RS-485 MODBUS & 4/20mA, 0/10 V |

| 89481: SWIFT V RS | RS-232/RS-485 MODBUS |

| 89483: SWIFT V PROFINET | RS-232/RS-485 MODBUS PROFINET |

| 89484: SWIFT V ETHERNET/IP | RS-232/RS-485 MODBUS ETHERNET/IP |