This enables the company to respond even better to the significantly increased demand, maintain the high-quality of its products, improve them further where possible, and shorten delivery times according to customer preferences. The modernization fits seamlessly into DMN-WESTINGHOUSE’s proactive growth strategy. In the coming years, the company will focus on further growth in Europe, Asia, the Middle East, and North and South America.

DMN-WESTINGHOUSE is resilient for the future thanks to its innovations, underlines the three-member management from its head office in Noordwijkerhout. Wim Korndorffer, CEO of DMN-WESTINGHOUSE, says: “We see increasing demand for our products from various markets and industries in the coming years. We are responding to this by innovating our production process by investing in modern technology”. Mario Janssen, Commercial Director at DMN-WESTINGHOUSE, explains: “By 2030, the world’s population will grow to 8.5 billion, by 2050 to 9.7 billion and by 2100 to as much as 11.2 billion. As a good result, the demand for food and products such as infant formula, coffee and pet food will increase dramatically, creating pressure to produce more in a shorter period. Future-proofing the dry bulk industry has, therefore, never been more important. With the innovations at our production sites simplifying our processes and installing various robots, the company is ready to meet that growing demand. It also allows us to better meet the ever-increasing demands for quality, safety, hygiene, reliability and ease of use.”

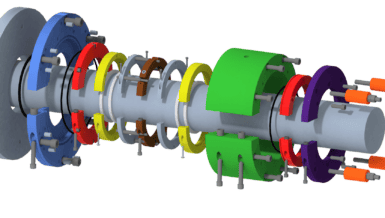

Ease of use in optima forma

DMN-WESTINGHOUSE assists customers in a wide range of industries, including infant formula, food, plastics, and the paint industry, with the challenges posed by the growth of the world population. Janssen: “For some time now, we have been focusing on the highest-quality rotary valves and diverter valves. For instance, we introduced the MZC-II rotary valve, which is highly distinctive in aspects such as safety and hygiene, and ensures a significant reduction in downtime risks, thereby contributing to lowering the total cost of ownership. Due to its double-sided opening, the new rotary valve is so intuitive to use that every professional in the workplace can use, open, clean and maintain it without detailed knowledge. No specific instruction or knowledge is required to operate the rotary valve, and optimal access to the drive end also allows extra thorough user-friendly cleaning.”

Focus on global growth

The producer operates globally and has an independent network of more than 70 distributors and its own production facilities in the Netherlands and Germany. Paul Silva da Cruz, CFO at DMN-WESTINGHOUSE, says: “We have the capacity to undertake huge projects. We focus very specifically on markets where growth is occurring. In addition to key markets such as dairy and food, pet food has also grown tremendously since the COVID-19 pandemic. Furthermore, we target emerging markets such as lithium-ion batteries and growth markets such as Asia, India, North and South America, and Europe. We are confident that with the modernization of our production facilities and our years of expertise, we can meet the global growth we anticipate in the coming years.”