BinMaster 3DLevel Scanners provide highly-accurate level and volume measurements for materials contained in bins, tanks, and silos. The sensor measures and maps the material, accounting for uneven surface topography when calculating volume. Each sensor comes with 3DVision software that reports low and high points and average material level based on average measurements. Some models provide a colorful 3D graphic illustrating the topography of material in silos.

Making inventory visible to multiple departments

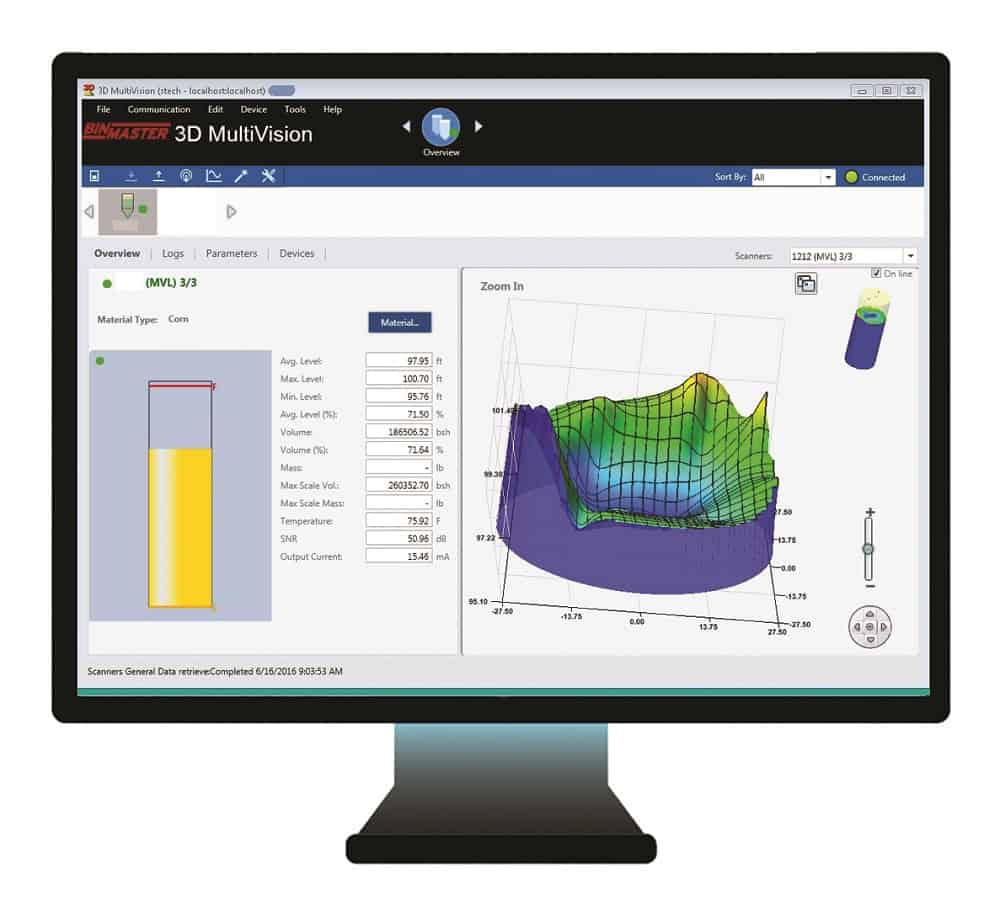

As inventory data is collected and processed, it can be shared on 3D MultiVision software across the entire organization, or with vendors using VMI, to improve purchasing, logistics, operational decisions, and financial management. With user-friendly setup and intuitive operation, each user can customize their screen to view all bins or a group of bins and color-code bins by material type. Users can set high and low-level alerts to be notified when bins reach critical levels. Because the software is installed on a company’s corporate LAN, there are no third-party applications or data access fees.

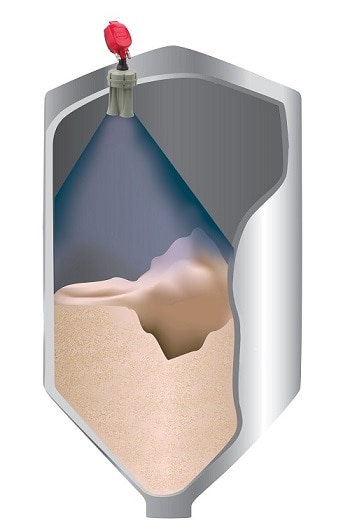

Measuring powdery bulk ingredients

Many ingredients tend to clump, pile unevenly, and flow unpredictably from storage vessels. Not only does this make monitoring the volume of material inside the vessel challenging; uneven disbursement of material can also take its toll on the storage vessel itself. Sidewall buildup can occur when material packs along bin walls. Ingredients can spoil if not properly rotated in the production process.

Some common applications for 3D level sensors in food processing include flour, meals, sugar, starches, brans, and other similar materials that are prone to pile unevenly and cling to surfaces. It is especially appropriate for food processors in industries such as baking, pasta, and candy where non-contact technology is a requirement for food safety. Grain millers will also find measuring ground soybeans, wheat, rice, or corn less troublesome when using the MV model of the 3DLevelScanner that also included a 3D visualization of irregular topography.