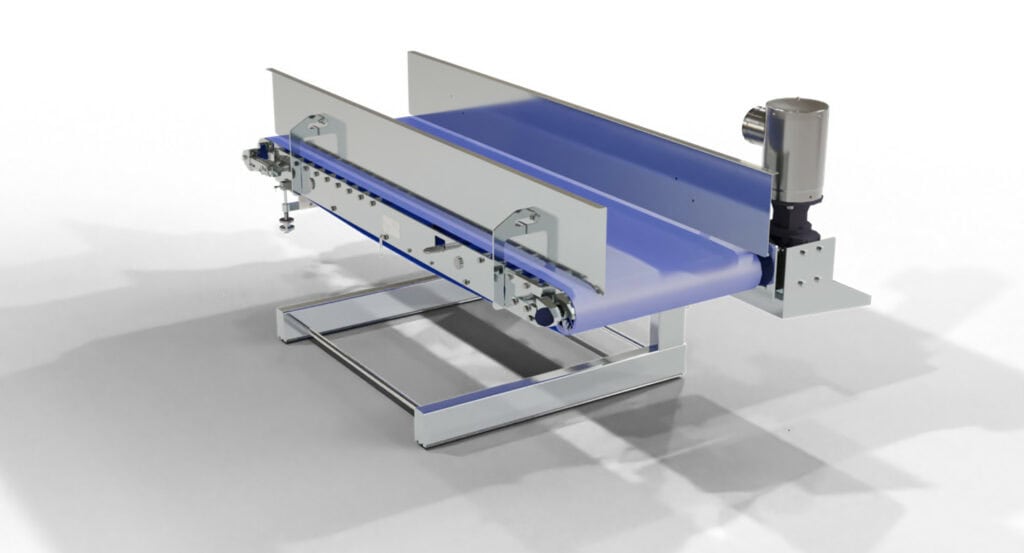

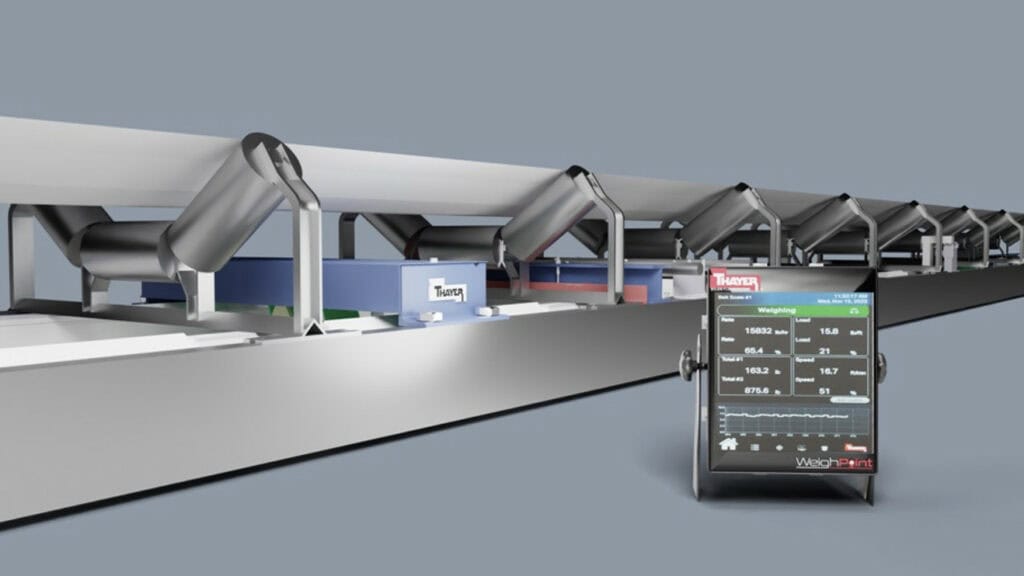

Thayer Scale is a leading global manufacturer of equipment for the continuous weighing industry. Founded in 1949, we provide engineered solutions for the food, energy and building products, and chemical and industrial industries. Our unyielding focus on product line specialization enables us to design and develop market-leading conveyor belt scales and gravimetric feeders.

Innovation—along with a continual commitment to product improvement —drives Thayer Scale’s strategy. We pride ourselves on delivering accurate, “Built to Survive” weighing systems and material-handling solutions that exceed customer expectations. Our customers—many of whom produce end-products for the world’s leading brands—consider us a trusted partner in their manufacturing efforts.