The venture not only achieved industry accolades but also set a new standard for innovation and creativity in the Bakery and Pastry Industry. Recognised with the Gold Award in the Innovation and Creativity category and the Electromechanical Equipment category at the Manufacturing Excellence Awards, the project symbolizes a transformative leap for both companies.

Aktina’s new Dry Mix plant, born from countless hours of meticulous planning and dedication, signifies a significant step towards fulfilling their vision of becoming a leading European producer of Dry Mix blends. The facility, boasting a remarkable maximum production capacity of 100 tonnes / 24h, addresses the escalating demand for white flour mixes, cocoa flour mixes, pastry creams, and an array of bakery and confectionery products.

The challenges encountered during the project were numerous and demanding. Transforming an old factory into a state-of-the-art production unit required extensive structural enhancements and architectural modifications. Yet, AKTINA’s commitment to meeting the most stringent international food production standards prevailed.

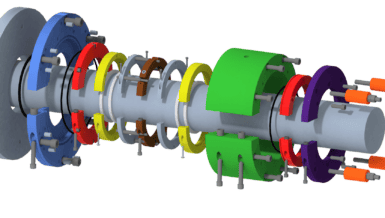

The pneumatic Conveying Systems enabled logistics optimization through fast unloading and packaging procedures, as well as short material supply routes.

Simultaneous production became possible with 10 mixing lines and 5 packaging lines, offering batch flexibility ranging from 500 kg to 5 tonnes and packaging from 300 grammes to 25kg, while minimizing machine cleaning time between batches with full process control and real-time connectivity with the ERP system.

The results are extraordinary. Thirty new jobs were created within a year, breathing new life into a dormant Greek food company that ceased operations in 2017. The dry mix unit’s productivity increased fivefold, coupled with a 35% reduction in production costs. AKTINA achieved a quadrupling of its capacity to simultaneously produce various dry mix end products, enhancing production flexibility.

The impact extended beyond borders, as the company’s export activity increased, allowing it to enter large and competitive markets abroad. AKTINA’s investment not only modernized their production but also created a model industrial unit, a leader in South-Eastern Europe and among Europe’s top dry mix plants.

The project’s success was not only in numbers but also in the creation of a modern working environment aligned with stringent health protocols. The utilization of Industry 4.0 principles, coupled with a state-of-the-art de-dusting system, showcases a commitment to sustainability and quality.

In conclusion, AKTINA and VRAYKOS’s journey in constructing the new dry mix production plant was a testament to vision, creativity, and perseverance. The lessons learned from this venture serve as a guide for future production investments. The legacy of Know How acquired throughout the project positions AKTINA and VRAYKOS as leaders in the ever-evolving landscape of dry mix production.