How has VRAYKOS managed to establish itself in the domestic market as a trusted partner of large multinational companies, as well as maintain long-term partnerships with the largest companies in the food industry?

VRAYKOS has had a strong presence in the Greek industry for over 30 years, and has managed to enrich its portfolio with a significant number of engineering projects in raw materials handling and process engineering for the production units of leading multinational companies. The company’s consistent growth over the years, even in difficult times for Greece, combined with its impeccably-qualified personnel, including the extensive technical experience and expertise of its engineers and the application of cutting-edge innovative technologies, has created the best possible conditions for VRAYKOS to stand out as an exceptional partner capable of delivering high quality standards for any industrial unit.

Having developed partnerships with the largest multinational companies in the food industry.

VRAYKOS has also developed all of the qualities required to ensure that these partnerships are sustainable over time. The company has continued to invest in new quality control systems for the construction of machinery systems, the training of its personnel in technical and safety issues, and the improvement of its production systems through the introduction of lean production processes, allowing it to successfully compete with internationally renowned companies of a comparable nature.

An extremely important factor in maintaining its long-term partnerships has also been the implementation of systems and installations that have been able to operate seamlessly, without technical problems, over many years, and in some cases, for decades. The technical support offered by VRAYKOS as part of its after sales services, as well as its immediate response to unexpected technical problems that cause downtime for production in manufacturing units with potentially high financial costs, are equally important factors.

What is the global market position of the multinational company PURATOS?

The multinational company PURATOS is one of the largest bakery, patisserie and chocolate manufacturers worldwide. It counts more than 100 years of progress in 100 countries around the world, with 93 innovation centers, more than 10,000 employees, and over 65 production facilities in 81 countries, developing innovative ingredients and solutions for bakers, patissiers, and chocolatiers around the world.

In what ways did VRAYKOS increase the production capacity of PURATOS factories, and what was the most difficult challenge in your collaboration?

The collaboration between PURATOS GROUP and VRAYKOS began in 2016, when PURATOS HELLAS was looking for companies to help develop the factory’s bakery department production facility. This first project for PURATOS was focused on meeting its requirements in combination with the high standard electromechanical equipment that the company was looking for. All machinery had to meet the high standards set by the most stringent construction specifications in the following areas:

- Ergonomic spatial planning of the facility

- State-of-the-art finishing of inner and outer machinery surfaces

- Highest requirements for easy and fast cleaning when designing machinery

- Certification of machines in accordance with ATEX (explosion-proof)

- Highly accurate weighing and bagging systems

- Intelligent systems for facility control-monitoring and installation

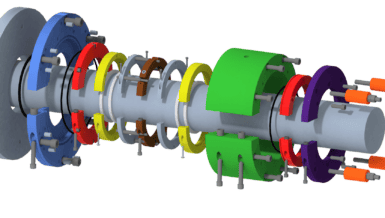

With these parameters set for this important collaboration with the PURATOS GROUP, VRAYKOS was able to respond to all the key issues, followed by the implementation of a high-quality technical solution. PURATOS HELLAS entrusted VRAYKOS with the development of the Group’s first major project, with extremely positive results. The system involved the development of a fully-integrated system for receiving, sieving, mixing, dosing, weighing, and bagging ready-made bakery mixes.

Several small-scale projects followed in factories in Greece and Romania, until 2018, the year in which the company undertook a project much larger than the initial one, which included a fully ATEX-certified installation for PURATOS patisserie production. This project was a major challenge for VRAYKOS, since it was a system that needed to take all those circumstances potentially requiring passive and active explosion protection into account during the process of sugar milling and pneumatic conveying.

Another step in the two companies’ collaboration was a large-scale project undertaken by VRAYKOS at the PURATOS plant in Bulgaria. With this project, VRAYKOS secured the approval of the Puratos Group for an innovative, large-capacity powder mixing machine with high homogenization and liquid injection capability that was able to meet the high-quality specifications of the special mixtures produced by PURATOS to the fullest extent. This machine is an innovative achievement for Greek manufacturing systems since it has the ability to deliver high-quality results.

Finally, improvements to the weighting and bagging systems at the PURATOS factory in Izmir, which included the installation of an evolved dosing, weighing, and bagging station, were able to ensure the factory’s maximum productivity as well as the highest possible weighing accuracy and simultaneous flexibility for quick and easy cleaning. These partnerships established Vraykos as a reliable partner of the PURATOS GROUP in Greece as well as overseas.

In the context of your collaboration with PURATOS, the first sugar milling facility in Greece to be fully ATEX-certified has been established. Tell us a little more about this innovative facility.

The excellent cooperation between the two companies was further sealed with the implementation of a highly demanding project, which included setting up a fully ATEX-certified installation for receiving, grinding, and feeding sugar to a mixing machine via pneumatic air transfer. The need to use explosion-proof equipment in sugar milling systems is imperative due to the highly explosive nature of the specific product (powdered sugar). This system was analyzed in depth by VRAYKOS, and its design was executed using explosion-proof equipment manufactured by a reputable European company. The protection provided in the installation is multistage: its design is intended to prevent the possibility of an explosion, but in the event that it cannot be avoided, arrangements ensure that the direction and expansion of the flame are controlled. The production system has been running smoothly and without issues for four years, demonstrating VRAYKOS’ ability to respond to food industry projects with high-quality solutions. This investment by Puratos represents a pioneering decision to establish the first fully ATEX-certified sugar milling facility in the Greek food industry.

How did VRAYKOS acquire its extensive knowledge of the bakery and pastry ready-mix industry through its collaboration with PURATOS?

At the beginning of the collaborative relationship with PURATOS, there were a number of issues that needed to be resolved effectively. Their resolution pointed the way to the successful completion of the projects. The distinguishing difference in a ready-mix production unit is that the electromechanical equipment has to handle multiple different materials on a daily or even hourly basis. In order for VRAYKOS to respond to these requirements and design and develop equipment with these characteristics, the company’s R&D department had to devote a considerable amount of time and manpower to the effort. The company made substantial investments in these new PURATOS projects in order to create machinery and equipment fully focused on and oriented towards the ready-mix industry.

Why does PURATOS continue to select VRAYKOS for its Greek and international projects?

VRAYKOS is well-known in the food industry for developing raw materials handling systems and for the high quality standards of the systems it implements. The company is one of the PURATOS GROUP partners approved for the execution and installation of integrated production units. It has installed bakery and pastry production units in our factory at Oinofyta with great success. The particular nature of the ingredients and mixes handled by Puratos worldwide requires special handling and equipment that meets very specific technical specifications. Vraykos came up with smart solutions and the right equipment to satisfy all these special requirements, which are mainly associated with quick and easy cleaning of the facility.

Puratos chose Vraykos based on the excellence of the solution it was able to offer, including the

potential to install customized machinery and equipment, adapted both to the special needs of the materials we use and to our existing production space. Vraykos is perhaps the only Greek company that is capable of meeting these specifications to such an extent.

The high level of technical staff training, strict adherence to schedules, the quality construction of the machinery, combined with the ability to employ customized systems and custom-made machinery, as well as automated solutions—these are just some of the benefits provided by VRAYKOS over the years that we have worked together. High-quality after-sales service is also essential for companies looking for a strategic partner to handle the maintenance and technical support of their production systems. Based on the systems that VRAYKOS has successfully completed to date, I am certain that our collaboration has a promising future.

What are the goals of VRAYKOS regarding its future collaboration with PURATOS?

VRAYKOS is a company that has marked a constant growth over the last three years, making important decisions and implementing radical reforms in its operations in order to ensure that it has the necessary capabilities to successfully implement large-scale industrial raw materials processing projects abroad. Following its partnerships with PURATOS Greece, Bulgaria, Romania, and Turkey, VRAYKOS intends to expand its cooperation with the group in order to become a strategic partner for the Southern European, Balkan, North African, and Asian regions.

Driven by research, development, and innovation, VRAYKOS is ready to face every new challenge and provide solutions for all issues within the industrial plants of PURATOS GROUP that require inspired technical solutions. The 4th industrial revolution (Industry 4.0) brings with it demands for new levels of automation and highly qualified technical personnel worldwide, and the need for reliable partnerships that provide technical solutions immediately in this new era points the way to companies such as VRAYKOS.