In late 2024, Guttridge had the pleasure of visiting Webb Automation, a leading manufacturer of packaging solutions for powders and granules. Mike Green, our Area Sales Manager for the region, visited Webb Automation as part of our ongoing relationship with the company.

Guttridge and Webb Automation Deliver Precision and Efficiency

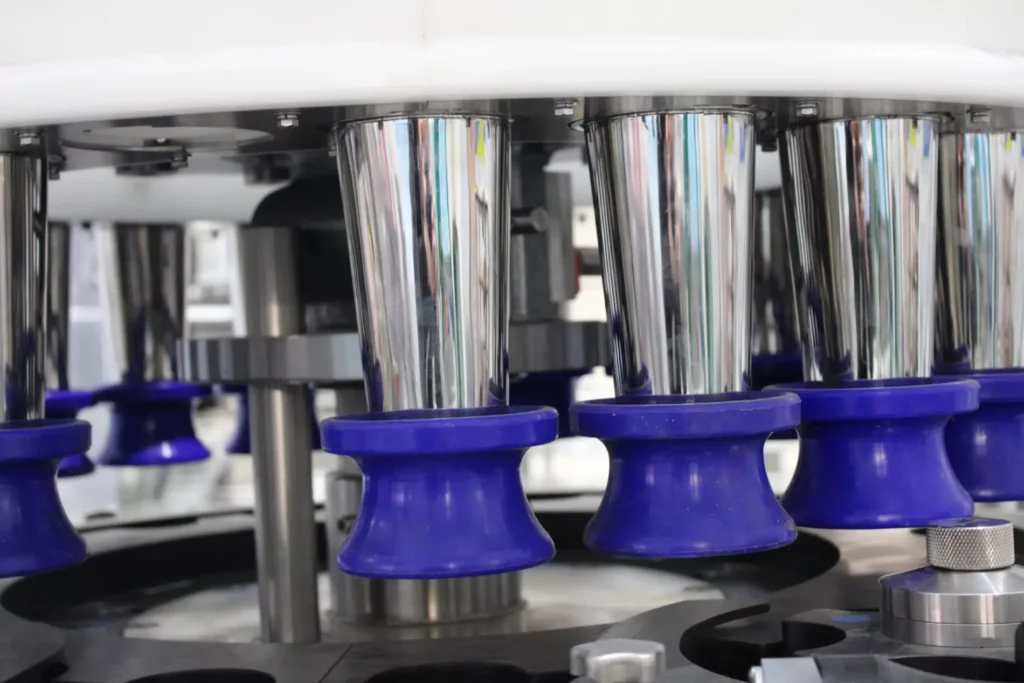

Webb Automation combines precision engineering with advanced automation to provide bespoke packaging solutions of all sizes. In operation since 1974, they have built a strong reputation for delivering high-quality equipment. Their expertise spans across food, pharmaceutical, and agrochemical sectors, where precision and efficiency are essential.

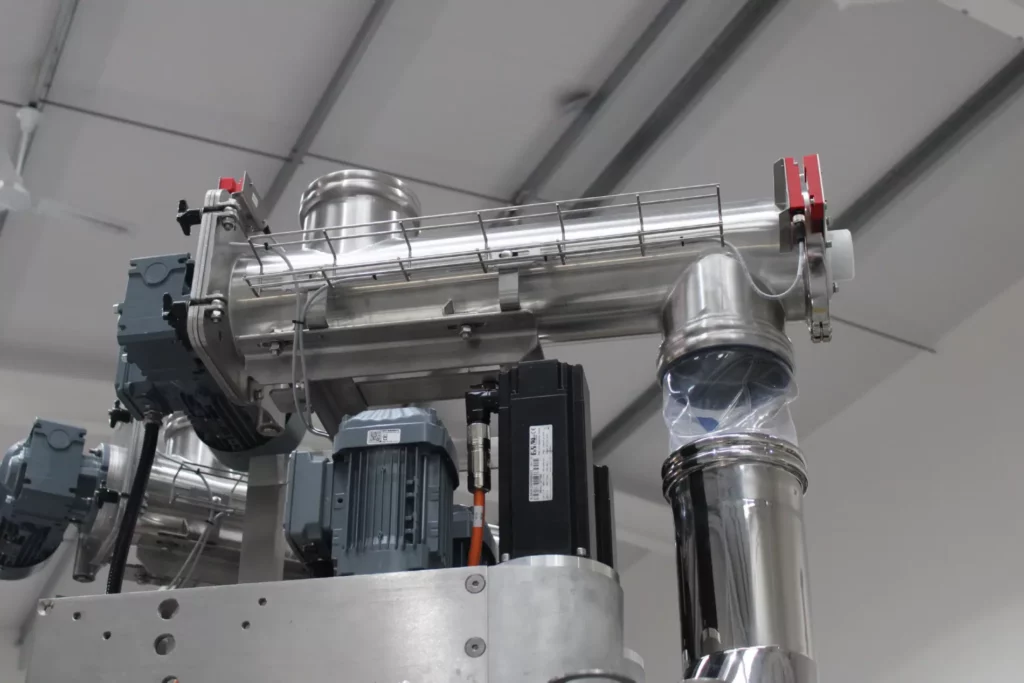

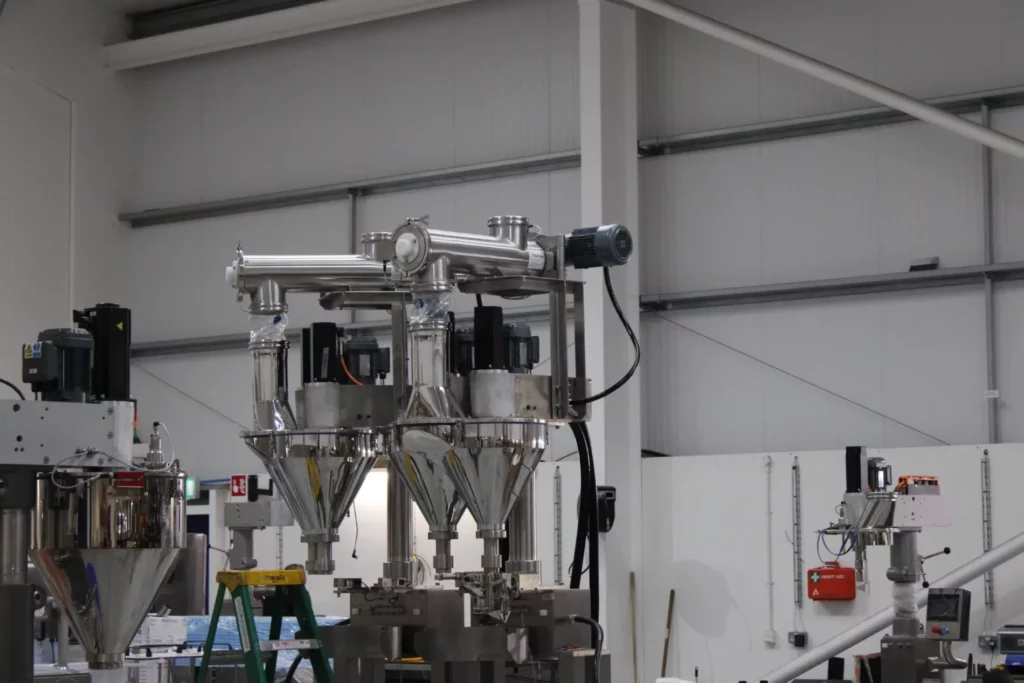

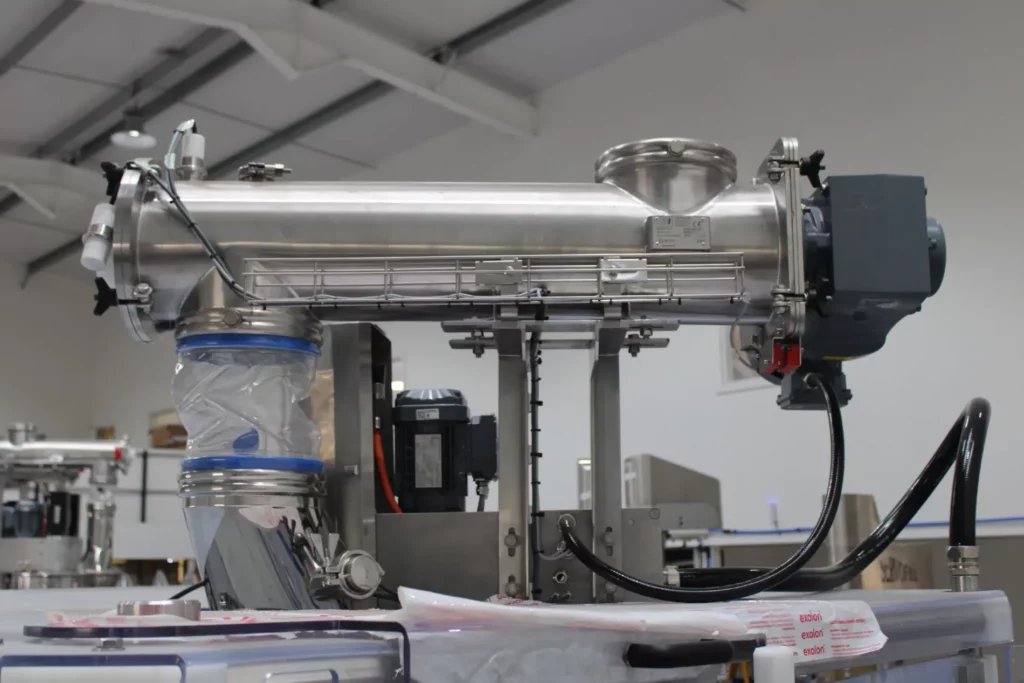

While Webb Automation excels in precise dosing and filling, Guttridge plays a crucial role by ensuring a consistent and reliable material feed. For example, the Augaflo Screw Feeder integrates seamlessly into Webb’s RotorPlant and Servo-Fill machines. By providing smooth and consistent feeding, Guttridge equipment ensures that Webb’s systems can operate at their full potential.

Augaflo Screw Feeder: A Reliable Solution for Modern Factories

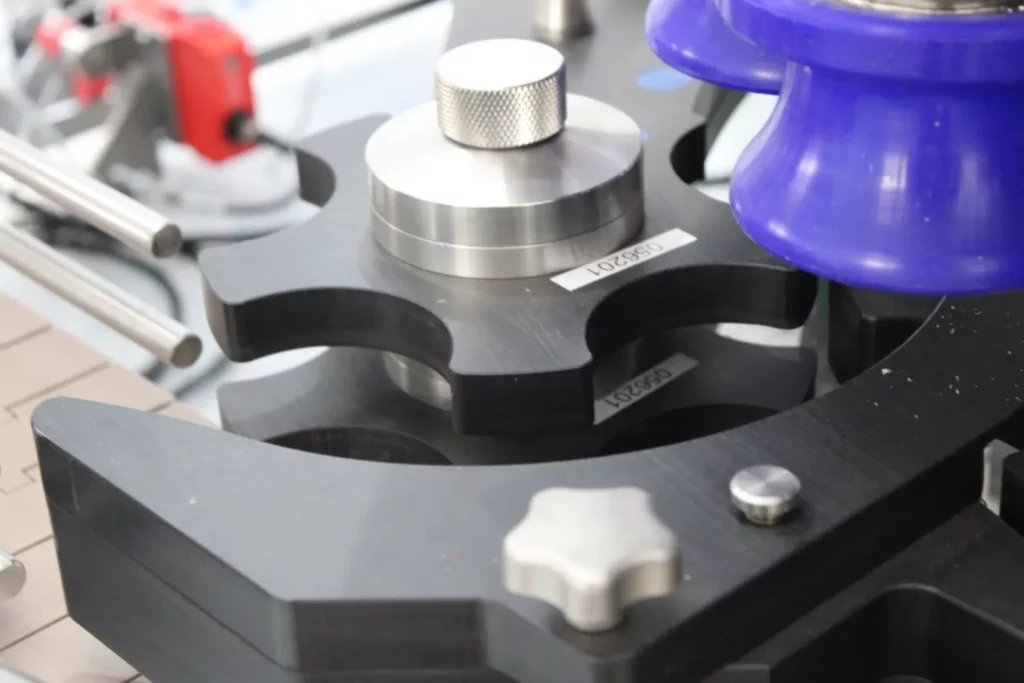

The Guttridge Augaflo is a high-quality, special-purpose screw auger designed to provide consistent and reliable feeding for a variety of bulk material applications. While it is primarily used as a screw feeder for auger filling machines, it is a versatile solution that can also be used in general-purpose screw conveyor and feeder applications where quick and easy cleandown is required.

When paired with a level probe, Webb Automation ensures that the Augaflo maintains a steady and controlled level of material in the dosing machines. This optimises performance and reduces the need for manual intervention, while minimising product bridging issues.

Constructed from 316 stainless steel, the Augaflo meets the high hygiene requirements needed for food-grade applications. Its quick-release clamping system simplifies disassembly and cleaning, while slip-fit joints allow for easy reconnection of screw auger sections. The Augaflo is specifically designed for frequent wet or dry cleaning regimes.

The Augaflo not only provides consistent and reliable feeding but also improves efficiency by reducing downtime for cleaning and maintenance. This level of reliability and adaptability makes it an invaluable component for customers like Webb Automation, ensuring their dosing machines operate at peak performance.

“Webb Automation have worked with Guttridge for many successful years. The Augaflo screw feeder has helped give our end users reassurance and consistency when running their Webbs filler.“

– Mr Ashley Goodwin, UK Sales Manager, GWA Webb Automation Ltd

Solving Common Industry Challenges

Without a reliable system like the Augaflo, dosing and filling machines can face a range of issues, including:

- Inconsistent Filling: Unsteady material flow can disrupt the accuracy of the dosing machines, leading to uneven fills, wastage, and inefficiencies.

- Product Bridging: If materials are simply dumped into hoppers, they may form blockages or bridges, halting the flow entirely and requiring engineering intervention to get the machine back online.

- Hopper Overloading: Without a consistent flow, hoppers risk overflowing, which may damage equipment or require time-consuming cleanup, potentially bringing production to a halt.

- Contamination Risks: With its easy-to-clean design and stainless steel construction, the Augaflo reduces the risk of product cross-contamination, which is particularly critical in the food and pharmaceutical sectors.

While Webb Automation focuses on efficient powder dosing and filling equipment, Guttridge provides solutions for multiple sectors, including food, fine chemical and pharmaceuticals. Similar applications in the food sector highlight how consistent material flow improves accuracy, reduces costs, and boosts efficiency. These case studies showcase the versatility and reliability of the Augaflo, making it a trusted choice for bulk material handling.

Transform Your Operations with the Guttridge FLO Range

At Guttridge, we are proud to offer bespoke solutions tailored to meet the precise needs of each customer. Our focus on collaboration and our extensive experience in the sector allow us to provide the right equipment for every job. The success of the Augaflo in Webb Automation’s operations is a testament to our commitment to providing reliable, efficient, and hygienic solutions for the food and pharmaceutical sectors.

Get in Touch

We would like to extend our sincere thanks to Ian Bowman and Ashley Goodwin from Webb Automation for their collaboration and insights. We greatly appreciate the opportunity to discuss the role our equipment plays in their processes.

If your operation faces challenges with bulk material handling, inconsistent dosing, or equipment maintenance, Guttridge is here to help. Our expert team can work with you to design and implement custom solutions that enhance your system’s performance.