Within the last years, customer inquiries received by NEUMAN & ESSER are geared to increased fineness with simultaneous top efficiency. In order to achieve this target, NEUMAN & ESSER has expeditiously created a new product family within no time: the classifiers GRC, DC, DCX, and the mills ICX, ICD, and PMX. Applying these innovative components, customers realize better product quality combined with lower manufacturing costs.

Existing Technologies

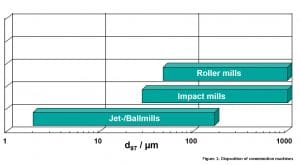

The fineness of less than 20 µm had not yet been achieved by pendulum mills or only in connection with products with a high solid density, so ball mills or even jet mills had to be applied (Fig. 1).

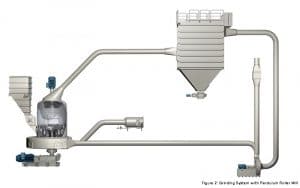

Conventional pendulum roller milling (Fig. 2) is an efficient comminution principle but was to date limited regarding fineness.

Objective

NEUMAN & ESSER’s goal was to identify the fineness limitations of roller mills and thus executed several development projects in order to investigate comminution, particle transport, and air classification (Fig. 3).

Development Process

Interdisciplinary expert team meetings were performed in order to collect ideas and proposals. Everything that used to be considered good and common engineering practice was challenged.

Solution approaches to achieve the new tasks were developed, and the ensuing drafts were then analyzed using Computational Fluid Dynamics (CFD). With these analyses, the potential for further improvement was identified and the design further optimized.

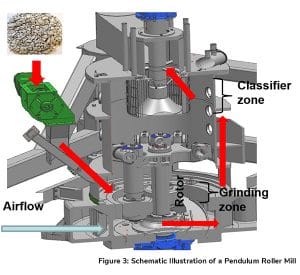

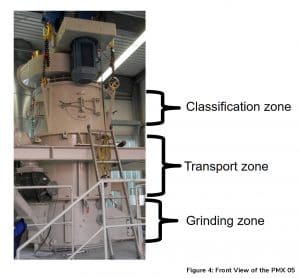

Thus, the grinding and classifying experts also developed the new PMX mill for fine grinding (Fig. 4).

The PMX provides unique means of material transportation and routing in order to separate the comminution and the classification processes, leading to greatly improved efficiency of both.

Results

The new PMX demonstrates its strength in a fineness range between 5 and 50 µm (Fig. 5). In this area, the PMX as a pendulum mill system offers a viable alternative to ball mills or even jet mills, thus establishing for the first time an actual option for those two comminution principles.

For product fineness between 20 and 50 µm, the PMX achieves up to 50% higher throughputs with simultaneous lower specific energy requirements than traditional pendulum mills (Fig. 6).

Here, the new NEA mill provides several decisive advantages: it only requires roughly half as much energy as a ball mill and, compared with a jet mill, the PMX is even more efficient. Furthermore, the PMX requires a lower pre-crushing ratio tor the feed material, which may have diameters up to 25 mm (1 Inch). Simultaneous drying of the material is also easy to realize. The integrated classifier with an innovative deflector classification module efficiently allows for sharp top cuts. This module is also available as an independent deflector classifier, the DCX, for operation in-line with any mill type, or as an off-line device.

Outview

The new Pendulum Roller Mill in the size PMX 05 is currently available for grinding tests at the Übach-Palenberg Test Center. This innovative solution provides NEUMAN & ESSER customers with a clear competitive advantage.