Designed for food, nutrition, chemical, and other manufacturers concerned with rising energy costs and sustainable production, the new drive system operates at a wide range of speeds while maintaining the same torque for consistent mixing with a wide range of materials and ingredients. The new system also reduces noise emissions for quieter operation, even during startup.

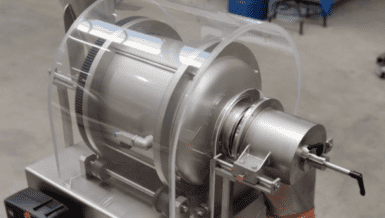

The GMS Multiflux mixer line is known for its proprietary, horizontal double rotor design that quickly and gently combines multiple powders and liquids in a homogeneous mixture within 30 seconds. The mixers integrate easily into fully automated operations and are compatible with Industry 4.0 and Internet of Things standards for fast installation and startup. Testing is offered in the company’s New Jersey test laboratory.