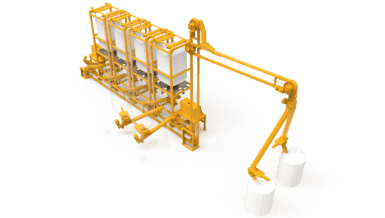

The comprehensive upgrade plan encompasses the installation of state-of-the-art conveying, weighing, and micro dosing equipment. Additionally, Acmon Systems will provide new electrical equipment and a cutting-edge process control system. The process control system boasts full redundancy functionality, ensuring uninterrupted raw material flow to the furnaces, even in the event of individual component failure. It will seamlessly integrate with Vetropack’s existing Siemens PCS 7 central distributed control system, (DCS) enabling streamlined operations.

With a steadfast commitment to quality, performance, and safety, the new installation will be fully dustproof and built to the highest industry standards. Acmon Systems’ extensive experience in bulk material handling, combined with their expertise in engineering, automation, and process control, positions them as the ideal partner for Vetropack’s batch house renovation project.

“We are thrilled to be entrusted with this significant project by Vetropack Group, said Mr. George Moshakis Commercial Director at Acmon Group. “Our team is dedicated to providing a comprehensive and robust material handling solution, leveraging our expertise and technical proficiency. We are confident that our turn-key approach, coupled with our commitment to sustainability, will contribute to the success of Vetropack’s production line upgrade”

From conceptual design to detail engineering, Acmon Systems has been the driving force behind this remarkable project. Acmon Systems assumes single-source responsibility for the batch house renovation, ensuring a seamless implementation and eliminating potential complications associated with multi-vendor coordination.