Whether you are looking to upgrade your mixer, integrate the mixer into your existing layout, create a new system design, or simply discuss your options, Spec Engineering is your trusted partner for mixing system design.

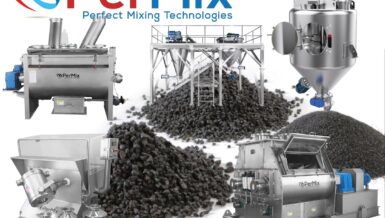

Our mixing capabilities include vertical, horizontal, plowshare, easy-clean, high shear, anchor or ribbon, continuous or batch, static mixers, and more. As a process solutions provider, we have extensive knowledge mixing a variety of materials, including powders, pellets, granules, and liquids, in a variety of industries. Our integration of a mixer into customer’s projects will result in increased quality control along with additional safety measures and increased efficiency.

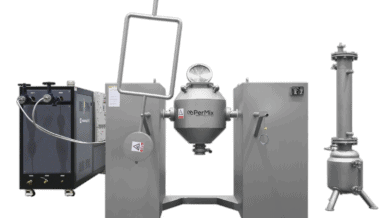

During a recent project for a full-scale bakery customer, Spec Engineering designed a new upgraded system that included a bulk ingredient receiver system, bulk bag unloading and mixing feed system, and a high-speed bulk bag filling system. This new system included a MixSys High-Efficiency Ploughshare 3D Mixer with Chopper System which features a spray nozzle manifold for enhanced process performance. The product is mixed and discharged into a Stirred Bunker 4 Screw Mix Ribbon System, providing continuous, homogeneous movement of the mixed product.

The original 15-minute cycle was decreased to 3-5 minutes per 6,000 lbs. mix cycle. Besides a reduction in time, the bulk bag filling process now has continuous and homogenous movement.

The customer quickly realized the increased savings that came along with having an updated system with efficient mixers. A second project was developed in which Spec Engineering replaced an outdated mixer with a new Ploughshare Mixer into an existing system. Without having to change out the entire system, the customer was still able to increase production and efficiency. The new mixer featured an extractable shaft which helped with increased sanitation during the cleaning process.