Spec’s automation team has a wholistic view of machine controls and integration along with the plant operations. Automation solutions can enhance any new or retrofitted process system to ensure ease of operation and troubleshooting for operators with layered SCADA.

Spec’s in-house control panel fabrication facility is a UL 508A, UL 698A, and UL 1203 certified location. The advantage of our control panel design services is the ability to create a system control panel scheme that is appropriate for a specific system. This includes distributed IO control panels and motor control panels that are the best fit for a production layout, ease of maintenance access, and reduction of field wiring.

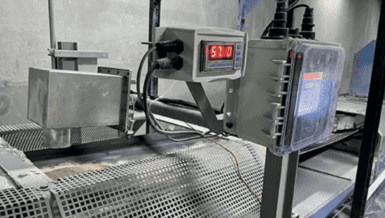

For one project, Spec designed electrical schematics and built the control panels for a new conveyer system. One master control panel included powder distribution and Compactlogix PLC for control of system I/O. There are three VFDs controlled over Ethernet/IP for conveyor control and an integrated touchscreen and thin client for operator control. A hygienic enclosure is used for the two operator control panels for this food plant. Eight power distribution panels are also in hygienic enclosures with watertight power connectors.

Even in projects where the automation scope may not be the initial focus, implementing controls and automated processes provides key upgrades for operators. The cost savings, increased efficiency, ability to trace batches, and batch repeatability is well worth the investment. With the combined resources of an engineering company with the capabilities of a manufacturing company, Spec’s automation team is ready to upgrade your process. Learn more about Spec Engineering’s automation capabilities at www.spec.engineering.

Spec Engineering integrated controls and automation on a conveyor system, which included hygienic enclosures for the food plant.

Spec Engineering’s automation team is UL 698A certified to design and fabricate control panels relating to hazardous location.