The Process: A variety of dry baking ingredients including flours, sugars, and shortenings are mixed and conveyed to a static bin fitted with an aeration device in the manufacturer’s lower level packaging area. The bin then discharges (direct gravity) into a square static tube with a dual auger batching 50lb increments for bagging, palletizing, then shipping.

The Problem: Each of the five product mixes utilizing the packaging line are classified as a non-free flowing, Class 4 material that is extremely pressure sensitive and adhesive-cohesive due to an increased moisture content. A slow and inconsistent gravity feed from the existing bin could not generate a continuous, uniform flow. This caused material build-up and compaction in the outlet and starved the packaging auger of product. Typical operating procedure required stoppage of the line approximately 15x per run to unplug, open, and unclog this critical area driving output down to a mere 33% of capacity.

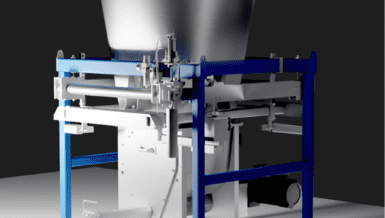

The Solution: A Metalfab Posibin™ designed specifically for the customer’s application is suspended from the ceiling allowing all existing equipment configured below to remain undisturbed. The straight side bin height is engineered to reduce compressive head loads. The bin, in conjunction with its integral bin activator, produces a consistent material density and facilitates uniform discharge. Its outlet interconnects directly with the packer to avoid long chutes or restrictions.

This configuration reduces residual product dust and minimizes areas of material build up that can impede flow. The Posibin™ uses a fully enclosed unitized vibrator/motor to generate a consistent, uniform flow from the bin outlet to the dual auger that batches the sugary, oily, bakery mixtures into 50lb bags with consistency and ease. The Posibin™, with its integral bin activator is constructed of 304 stainless steel, include sanitary features, and are each fitted with an access door for ease of cleaning during product change-over.

Maximum Capacity: Previously, running at 33% capacity, the packaging line output was 1-1/2 to 3 bags per minute – three per minute being rare. Frequent stoppages – as many as 15 per run – were required to free product build-up that was clogging the bin outlet/feed to packaging auger. Today, the

line only stops for product change-overs and output is now 6 to 7 bags per minute – an increase in output that exceeds 300%.