At the time of this writing, their manufacturing utilizes nearly a dozen Chain-Vey tubular drag conveyor and tube chain conveyor systems that reliably convey ingredients used in making their popular foods for exotic animal feed.

The variety of ingredients their Chain-Veys transport includes black sunflower seeds, thistle seeds, millet, and safflower just to name a few. Previous to owning Chain-Veys, Premier used a variety of screw conveyors, pneumatic conveyors, and bucket elevators. This made for a time-consuming array of cleaning methods and training, as well as differing quality of ingredients after being handled. One example was when conveying certain seeds that were fragile, which were prone to break during pneumatic conveyance.

“Pneumatics were good for getting around tight corners, but some of the seeds couldn’t handle them,” says facility manager Francis Connelly. “Then we had bucket elevators, but they’re exposed in the open and dust gathers in them and they’re not easy to clean.”

Premier installed their first Chain-Vey in 2014 and over the years kept replacing the rest of their conveyors. Their nearly dozen Chain-Veys offer all the benefits of each conveyor type, but without any of the drawbacks (read more on the pros and cons of each conveyor type). With Chain-Vey, Premier got everything they wanted: an enclosed, space-saving design, with reduced power consumption and noise, all the while reliably transporting ingredients and preserving integrity.

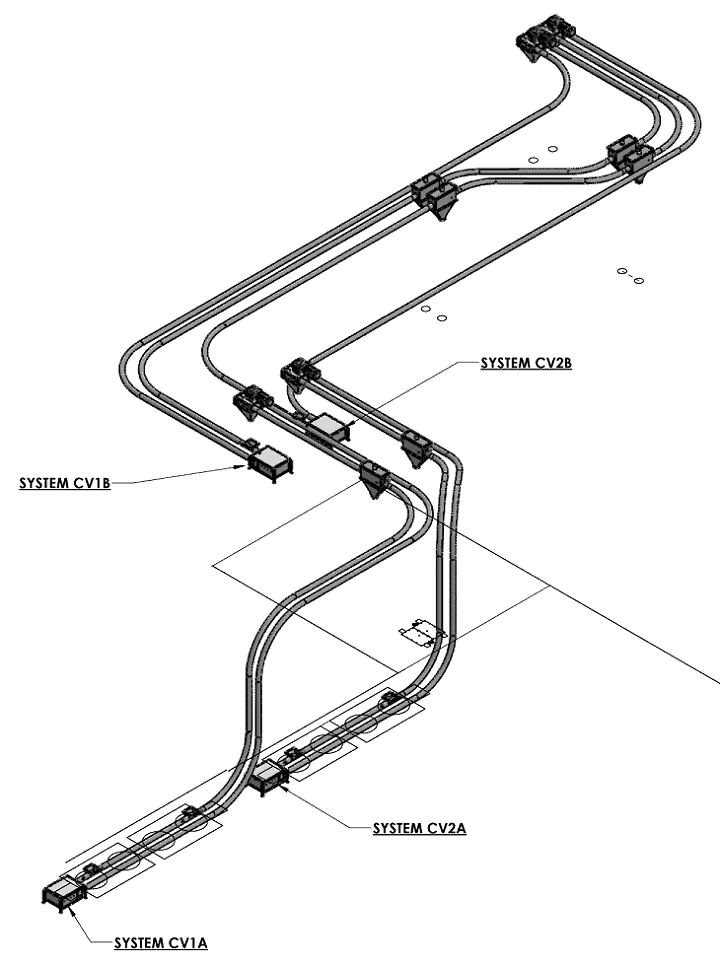

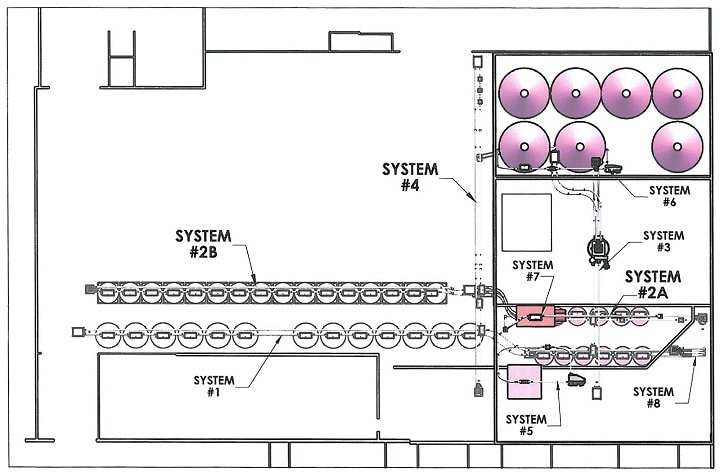

Drawing of one cluster of systems

- Product bulk densities between 35 to 40 lb/ft3

- Maximum conveyance rate of 650 ft3/hr

- 4″ conveyor diameters with Schedule 10 304 stainless steel

- Carbon steel chain with split UHMW pucks

| System CV1A | System CV1B | System CV2A |

| 148.5 ft circuit length | 166.5 ft circuit length | 114.5 ft circuit lenght |

| (6) 90 degree 60 CLR elbows | (3) 90 degree 60″ CLR elbows | (2) 90 degree 60″ CLR elbows |

| (1) pneumatic rotary discharge | (1) 90 degree 40″ CLR elbow | (2) 90 degree 48″ CLR elbows |

| (2) inlets with flow baffles | (2) 34 degree 36″ CLR elbows | (2) 50 degree 36″ CLR elbows |

| (2) pneumatic rotary discharges | (1) pneumatic rotary discharge | |

| (1) inlet | (2) inlets with flow batffles |

Facility overview

Notable facts about Premier’s installations; System #2B has 16 discharges and System #1 has 19 discharges. Very few limitations exist when designing a Chain-Vey system. No matter how demanding your project needs are, Chain-Vey is likely able to exceed your system specifications.

Life with Chain-Vey

Premier Bird Foods is not unique in their situation. Like many customers, they started out with conveyors that fit their budget and needs. But they needed a better system as they grew. Even when they settled on tubular drag conveyors, they meticulously compared competing manufacturers. Some manufacturers specialize in agricultural feed or cable-only designs; which depending on your application may or may not be an ideal fit for you. Premier chose to move forward with Chain-Vey because it was the clear choice of many other installations like the Willy Wonka of Coffee installation, Ballast Point, and Bakery Co. These examples assured Premier of the kind of quality system they were getting.