This magnetic separator removes metal particles and weakly magnetic stainless steel particles from powders as fine as 30 µm in the food, chemical, ceramic and plastic industries. The Easy Clean flow magnet is suitable for large product flows and distinguishes itself by the very

High separation yield

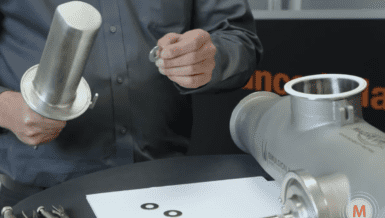

The thick, Ø50 mm magnetic bars provide a very high separation yield, have a deep holding field and a high flux density. This ensures that even grade 316 stainless steel particles are captured. To make sure that all particles touch the bars, a deflector is fitted. The large space between the bars results in a significant increase in capacity of the passage, which is particularly beneficial when it comes to poorly flowing powders.

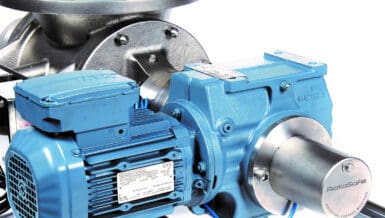

Automatic cleaning

Cleaning takes place during a production stop. The product chute must be

The pneumatic magnetic bars simplify the cleaning process. The guide takes the magnetic bars outside the product channel, after which the magnets in the bars are blown outwards. A plate then retains the captured metal particles, after which they fall into a collection tray. Sensors detect the position of the magnets. After cleaning, the magnets return to their original position and the product flow can be restarted. With the help of a connection box, it is possible to connect and control the magnet via the central control room. A control box with PLC is optional.

Redesign

The modified design is dustproof towards the outside. At the top, a cover plate with