The process equipment manufacturer had previously collaborated with IEP on various projects in Europe, however this was the first opportunity to propose a protection system which was fully compliant with North American standards and regulations.

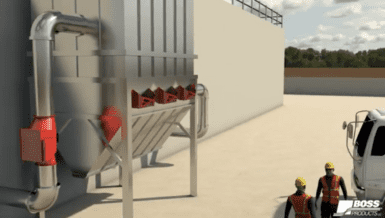

In this particular case the project consisted of an installation of a completely new spray drying process, including a fluid bed dryer, dual, cyclones and baghouse for dust removal and collection was all of which were being added to an existing dairy facility. The operator of the plant was acutely aware of the risks of industrial explosions, as one of their competitors previously suffered an explosion event in a similar process, and while fortunately there were no injuries to personnel, it resulted in significant plant damage, downtime and financial consequences.

The first stage of determining a protection strategy was to conduct material explosion testing in the IEP Technologies’ Combustion Research Center, based in Marlborough, MA. This independent laboratory has been specializing in the combustion characteristic testing of dusts, liquids, and gases for over 35 years, performed in accordance with the requirements of recognized standards bodies including ASTM, OSHA, US DOT and UN.

Firstly, as the whey drying process was governed by USDA regulations, any devices or sensors coming into contact with the product had to be compatible with and suitable for the plant hygienic cleaning in place (CIP) regime which employed a high temperature/highpressure cleaning phase. Secondly, in view of the relatively large vessel sizes and short runs of ductwork between vessels, multiple types of detection were required to shorten the isolation distances. This resulted in dual detection methods being used – combining pressure and infra-red techniques to allow for suppressor placement closer to vessel inlets and outlets and to prevent any explosive events from propagating to interconnected vessels.

The final explosion protection system selected consisted of dual high-temp detectors, rapid acting Piston Fire II and 5” High Rate Discharge suppressors and explosion relief panels, linked back to IEP’s EX8000 multi-zone control panel and split into 6 operational zones which allow for future, expansion up to a maximum of 16 zones.