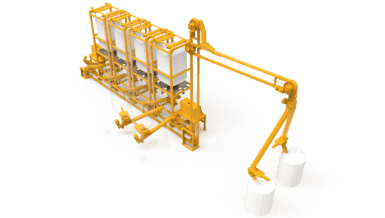

The parts in contact with the product are made of stainless steel or non-stick material. The body is made from a single cast of materials allowing the powder to move freely in the chamber with the vibrations produced only by the machine operation. The hopper can be made of various materials according to the powder to be processed. Where the product has a tendency to be compressed, the standard dosing tool can be changed, replacing the continual spiral with a memory wire spring, to avoid compacting the material. The constant-speed screw feeder has a volumetric capacity calculated by the volume of material in the section of one complete spiral and the diameter of the screw so that the dosage varies with the number of spirals. STM guarantees the best accuracy in connection with the weighing system and dedicated PLC or remote control.