The new enclosure is designed to accommodate a separate process fitting to allow the enclosure to rotate 270 degrees after the unit is threaded to the mounting plate. This feature ensures the user can always install the two, ¾” conduit entries pointed down to the ground to prevent unwanted moisture from entering or harming the rotary.

On the inside, the BMRX-100 features a simple mechanical design. It has a 10 Amp, 250 VAC max SPDT relay switch and is powered by a USA-made gear motor made in BinMaster’s Nebraska plant.

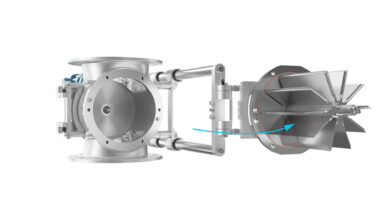

BMRX-100 Motor voltages include 115 VAC, 220 VAC and 24 VAC to suit any plant processing operation. The BMRX is adaptable to many bulk solid materials using top and side mounting plates with half and full couplings.

BinMaster offers a wide selection of 19 paddles for light, medium, and heavy-weight materials including collapsible paddles so there’s no need to go into the vessel to install or replace the rotary.

There are various stainless steel process connections for corrosive or caustic materials. Plus, BinMaster offers galvanized and stainless-steel extensions for top-mounted rotaries used for high-level alerts.

The BMRX-100, like all BinMaster rotaries, is used for process control for high, demand, and empty level indication. Most commonly it’s used for level detection and point level alerts in vessels containing bulk solids.

It can also be installed for overflow prevention. In particular, high-level alerts to avoid overfilling or to prevent material outages using low-level alerts to eliminate empty vessel conditions. It can also detect overloaded or empty conveyors and alert when chutes get clogged with material.