The BMR-100 rotary sensor offers simple, electromechanical measurement for ordinary storage and processing operations. It is generally wired to light or horn to alert to high or empty levels.

The new BMR-100 rotary is an affordable level switch to alert to vessel levels in solid materials with a bulk density of 2 lb. to more than 100 lb./cu. ft.

A rotary paddle switch is used across many process industries. Some of the more common industrial applications include:

- Agriculture for storage bins containing grain, seed, feed, fertilizer, or bulk ingredients.

- The construction industry storage silos for concrete, cement, or roofing granules.

- Mining and minerals such as sand, gravel, aggregate, coal storage, and surge bins.

- Plastic molding operations to detect level of plastics pellets in silos or hoppers.

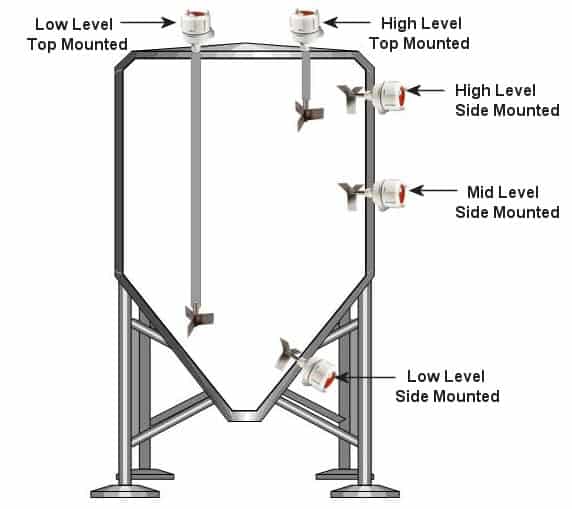

This versatile level indicator is offered with a wide range of accessories. There are 19 different paddles for light, medium, and heavy bulk solid materials. Collapsible paddles are convenient for installation without entering the vessel. Carbon and stainless-steel mounting plates options come in 0°, 10°, 20°, and 30° angles for top mounting on sloped roofs.

Point-level alarm panels display vessel level conditions via a blinking light and an audible alarm with up to 24-level indicator stations. Quick-disconnect accessories can be added to replace hard wiring. They make BMR-100 easy to install and remove for cleaning, maintenance, or replacement. An adjustable top mount allows you to change the high-level threshold simply using an adjustable coupling that can be moved up and down a 72” shaft.