When these materials are bulk solids, such as powders, granules, and pellets, then a solids flow meter is the perfect choice for providing the information necessary for improving process efficiency, providing cost control mechanisms, and for adequately maintaining quality assurance. The CentriFlow Meter from Eastern Instruments is just such a solids flow meter, that provides a highly accurate, real-time mass flow measurement solution that improves material handling and process optimization across nearly every industry.

How the CentriFlow Meter Works

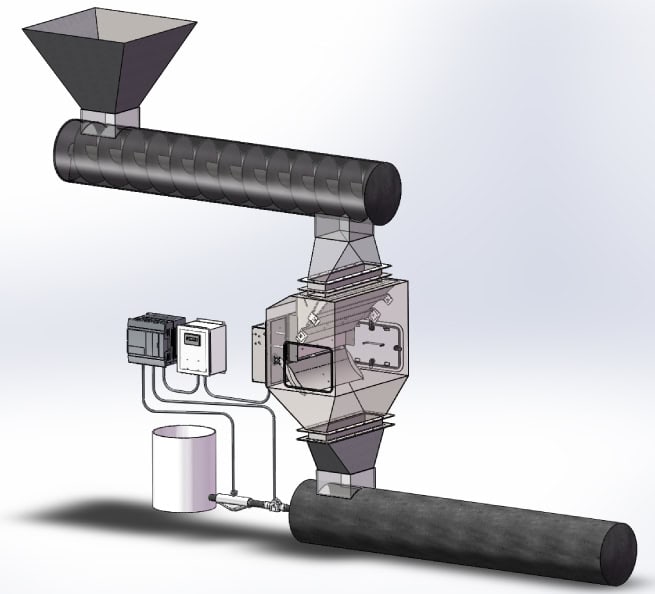

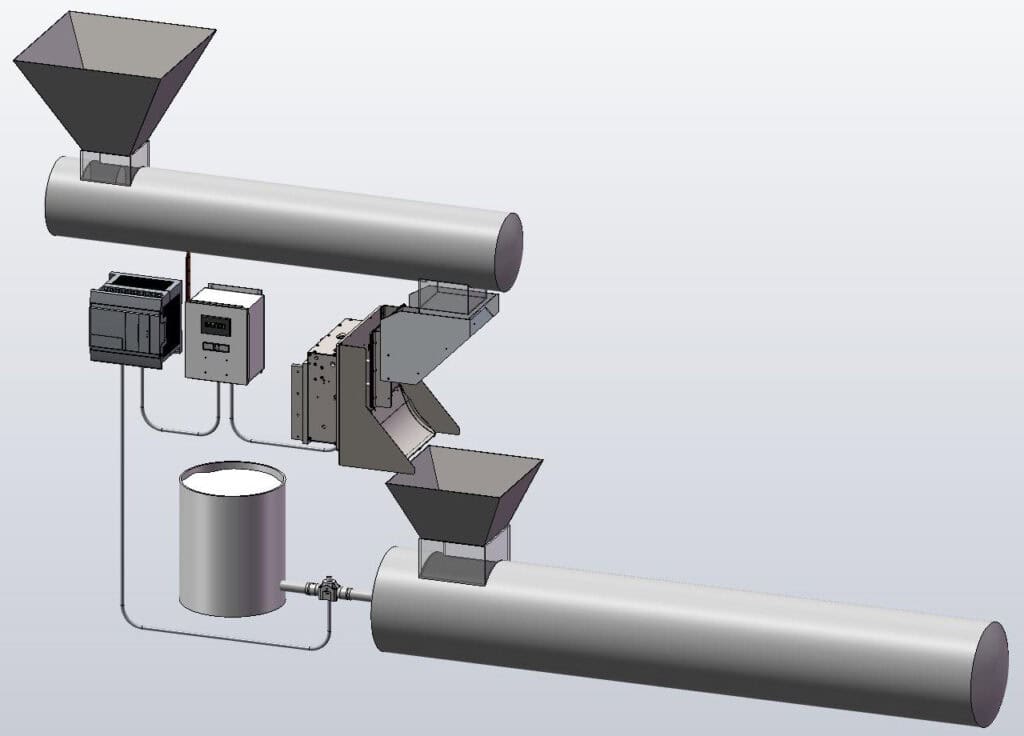

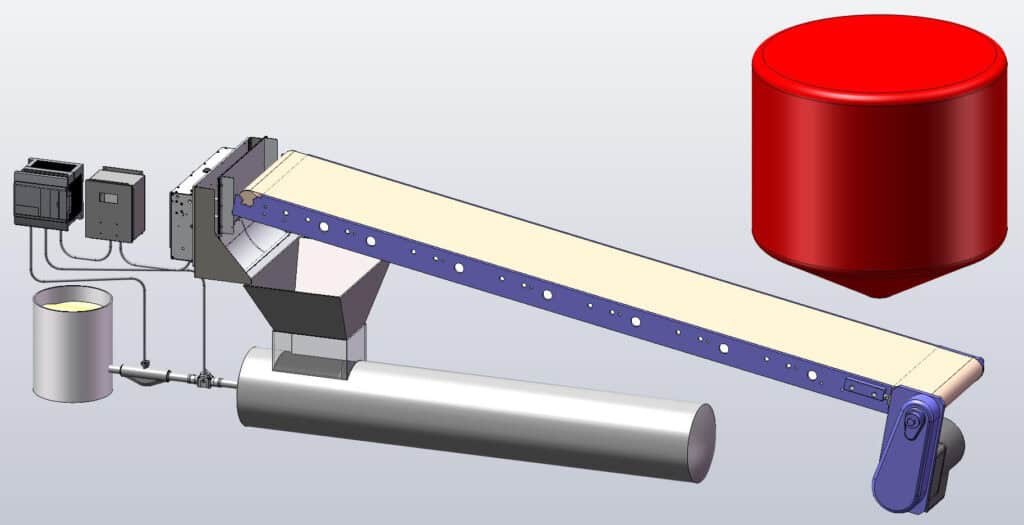

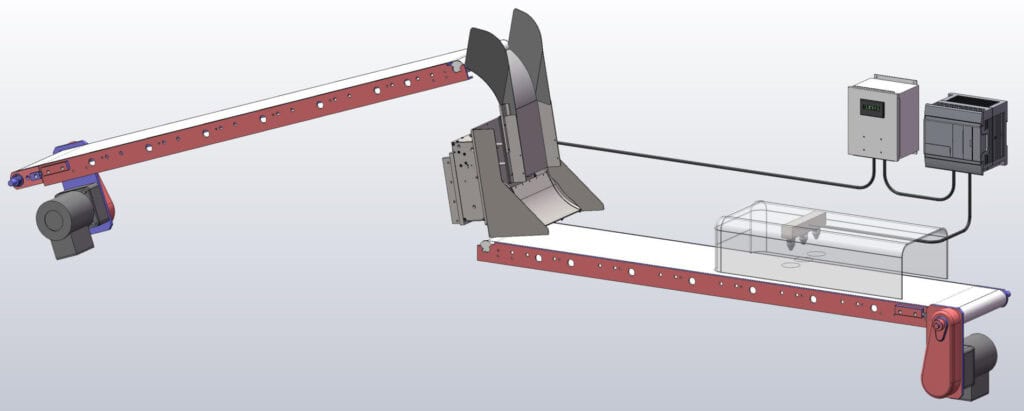

The CentriFlow Meter uses a centripetal force measurement principle. As material is forced to slide across a curved sensing plate, the centripetal force created, which is proportional to the mass flow of the product, is measured by a high-precision load cell, that converts the force into an electronic signal that is interpreted into a precise and accurate, real-time, continuous flow measurement. The result is the industry-leading accuracy, on most flowable solids, of within +/-0.25%.

Where the CentriFlow Meter Works

The CentriFlow Meter is widely used across a variety of industries and for many applications that require precise bulk material flow measurement. Below are just a few examples of where and how the CentriFlow Meter has been utilized in the past:

Food and Beverage Industry

- Accurate dosing of various ingredients based on a recipe. Accurate ingredient dosing is essential for consistency in food production and the reduction of waste. PRODUCTS: Flour, Sugar, Barley, Hops, Malt, Salt, Cocoa Powder, Seasonings

- Blending of various ingredients for finished product mixtures of various snacks. Ensuring proper blends of the various ingredients within a mixed container is important to ensure customer satisfaction and to maintain tight control over the supply of expensive ingredients. PRODUCTS: Nuts, Rice, Beans, Dried Cranberries, Chips, Pretzels, Snack Foods

- Ratio controlling the amount of seasoning or coating being applied to chips, candy and snack mixes. Under applying seasoning will result in unsatisfied customers and over application will result in waste and inflated costs. PRODUCTS: Potato Chips, Nuts, Candy, Tortilla Chips, Pretzels and Snack Crackers

- Measuring incoming and outgoing product from machinery such as roasters, dryers or mills. By measuring product as it enters and exits specific machinery, the machinery can be run at its optimal flow rate, which produces the most end product at the least cost and with the least amount of waste. PRODUCTS: Coffee Beans, Cocoa Beans, Whole Corn/Meal

Chemical and Pharmaceutical Industry

- Ensure precise material flow for product quality and regulatory compliance. The CentriFlow Meter offers precise, repeatable measurements and with an accuracy of within +/-0.25% on many materials, it makes an ideal solution. PRODUCTS: A variety of powdered chemicals across the industry

Agricultural and Animal Feed Industry

- Measuring incoming and outgoing product from machinery such as mills, in order to optimize the machine’s output. PRODUCTS: Corn, Wheat, Oats, Soybeans and other Edible Beans

- Measuring commodities as they are loaded into trucks and railcars, readying them for transport. Accurately filling trucks and railcars reduces the likelihood of overfilling, which leads to unloading the vehicle and having product removed, or underfilling, which leads to additional vehicles being needed to transport the same amount of material. PRODUCTS: Grains, Beans, Meals, Flours

- Accurate dosing of various ingredients based on a recipe, during the manufacture of pet food kibble. PRODUCTS: Grains, Poultry Meal, Bone Meal

- Ratio control the amount of spray on nutrients for coating pet/animal feed. PRODUCTS: Pet Food Kibble, Feed Pellets, Poultry Crumbles

Plastics and Recycling Industry

- Measuring the total weight of finished plastic as it is being manufactured. The CentriFlow Meter can be used to know the output capacity of the finished product for an entire process line or plant. PRODUCTS: Plastic Pellets, Plastic Regrind

- Measuring product during the recycling process to ensure proper material blending and process efficiency. PRODUCTS: Plastic Flake, Ground Film, Shredded Plastic Bags

Construction and Cement Industry

- Accurate dosing of various ingredients to improve mixing accuracy and reduce material waste. PRODUCTS: Roofing Granules – SHINGLES, Wood Chips – OSB, Crushed Glass – PAINT, Gypsum – WALLBOARD, Kiln Dust, Lime, Flyash – CEMENT

Energy Production Industry

- Batching of various fuel sources for burning during the combustion phase of energy production. The proper fuel to air ratio ensures a cleaner combustion cycle, which results in lower emissions and less costly clean up procedures. PRODUCTS: Wood Chips, Cherry Pits, Construction Debris, Chopped Corn Husks

Why Use the CentriFlow Meter? (Key Benefits of the CentriFlow Meter)

High Accuracy and Reliability

The CentriFlow Meter provides highly accurate mass flow measurement for a wide range of bulk solids. For most flowable solids, the CentriFlow Meter is capable of accuracies within +/-0.25 – 0.50%.

Maintenance-Free Operation

Unlike traditional impact flow meters or mechanical feeders, the CentriFlow Meter does not rely on moving parts that are susceptible to wear. The entire range of motion for the CentriFlow Meter is less than 0.015 in (0.38 mm), meaning that the meter is practically a static device. With no moving parts in direct contact with the product, the CentriFlow Meter experiences minimal wear and tear, and provides long-term reliability with minimal maintenance and very few spare part requirements.

Real-Time Flow Data for Process Optimization

The CentriFlow Meter delivers continuous, real-time mass flow data, allowing operators to monitor and adjust material flows instantly, improving overall process efficiency. The flow rate is updated every 100 milliseconds.

Easy Integration with Existing Systems

The CentriFlow Meter seamlessly integrates into existing process control and automation systems. It offers a standard 4-20 mA output equivalent to flow, as well as a pulse output that is equivalent to total. An Ethernet/IP Communications protocol is also available which allows for back-and-forth communication with the flow meter, enabling simple connection to PLC, SCADA, and industrial monitoring systems.

Versatile Material Handling

The CentriFlow line of meters offers a variety of configurations and options that align with a vast array of different types of materials. Whether you are trying to measure fine powders, pellets, coarse granules, or irregularly shaped particles like whole leaf tobacco, tortilla chips or shredded plastic bags, the CentriFlow Meter is designed to measure nearly everything, making it suitable for almost anything.

Installation and System Compatibility

The CentriFlow Meter is designed for easy installation in any gravity-fed system, and does not require the large straight upstream runs that most impact meters require. The CentriFlow Meter is typically installed directly after feed devices like rotary valves, screw conveyors, belt conveyors, etc. Its compact design allows for very simple retrofit applications where space is limited, while still providing the highest level of accuracy and reliability in mass flow measurement.

Why Choose the CentriFlow Meter from Eastern Instruments?

Eastern Instruments is a proven leader in bulk material measurement and flow control solutions, offering innovative, high-quality equipment to optimize nearly any industrial process. The CentriFlow Meter is a premier choice for businesses looking for precision mass flow measurement with minimal maintenance and maximum reliability, all at a reasonable cost.

For more information on how the CentriFlow Meter can improve your material handling processes, visit the official product page on the Eastern Instruments website.