Measurement requirements

To match the supply of sugar to its production and make the filling process as efficient as possible, Pfeifer & Langen relies on level monitoring. In the past, a plumb line has been used to check the level manually. This method is extremely time-consuming as it required a company employee to regularly climb onto the intermediate floor of the silo and check the level at different spots through manholes. In addition, opening the silo presented the risk of an accident and of the product coming into contact with unwanted substances. In an effort to automate level measurement, Pfeifer&Langen were looking for a permanently installed measuring solution. Due to the medium and the size of the silos, non-contact measurement was preferred. When selecting the measuring principle, the prevailing conditions in the silo had to be taken into account. This included the weakly reflective product surface of the sugar (εr – value: 1.8) as well as the formation of a variety of angles of repose in the silos. Depending on the grain size, dust can build up inside the silos. Under certain circumstances it could be several minutes following the filling process before the sugar compacts and settles. For this reason, ultrasonic measurement was eliminated early on as a viable solution.

KROHNE Solution

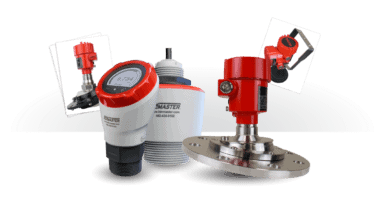

The customer decided on the OPTIWAVE 6300 C non-contact radar level transmitter. Boasting a 24…26 GHz FMCW radar, the measuring device is designed for use in extremely dusty atmospheres. It features a patented, elliptical drop antenna that does not clog up, even in the presence of extremely adhesive media such as sticky sugar dust. Due to the measuring height and the low dielectric constant of the medium, in this application the large drop antenna (DN 150) made of polypropylene (PP) was selected. It was installed using a G ½ process connection. The devices were installed in the existing manholes in the intermediate floors of the silos. The shape of the OPTIWAVE 6300 antenna concentrates the radar beam which helps to achieve the measuring range required for this application. The measuring signal (4…20 mA) of the OPTIWAVE 6300 is transmitted to a control unit and the level is displayed in the control system.

Customer benefits

Pfeifer & Langen benefit from continuous level measurement and can now reliably monitor the amount of sugar available in the silos, even when dust has built up. All information is automatically made available in the inventory management system. This prevents a lack of supply, any resulting disruption in production and overfilling of the silos. As it is no longer necessary to manually check the level, the customer saves time and human resources. In addition, the OPTIWAVE 6300 incurs no further operating costs. While a crust of dust builds up on the antennas of other measuring devices and must then be removed manually or with the help of a purging system, the drop antenna of the OPTIWAVE 6300 is maintenance-free. As a result, Pfeifer & Langen did not have to install a compressed air line for purging, which saved energy costs, for example. And, as the silos no longer have to be opened, the integrity of the granulated sugar is guaranteed. The customer is extremely satisfied with the measurement in the concrete silos and is currently looking into further use of the OPTIWAVE 6300 in smaller silos on site.