The wear was mainly due to the corrosive nature of the product and the strength of the chain installed.

The corrosion was wearing the chain links and pins quite rapidly and the low chain strength lead to rapid elongation of the links. These 2 issues combined resulted in many chain breaks and a lot of production time loss to maintenance on the conveyors.

Solution

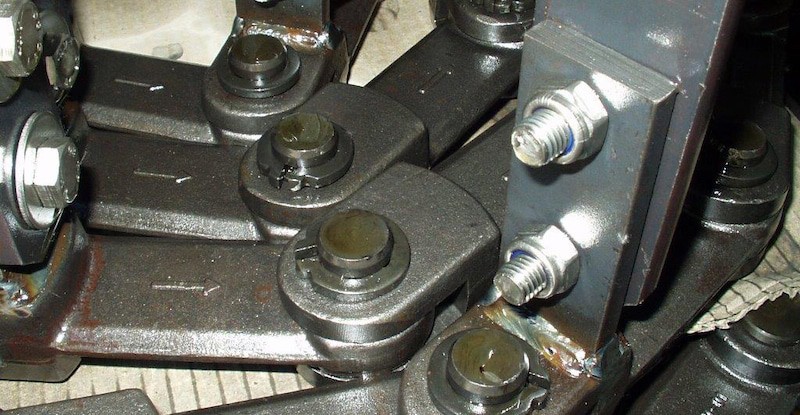

We offered the 4B142HAD chain links with pins in AISI420 and circlips in AISI304. These pins had a higher resistance to corrosion and the HAD link is 33% stronger than the standard HA link. Because the link is through hardened, it remains quite strong in its core, even if the outer layer wears away. The chain solution was coupled with new sprocket segments made from Hardox 450 and treated to improve the corrosion resistance.

Results

The changes made to this chain have improved the life of the chain conveyor by at least 50%. These improvements are more substantial when the maintenance of the conveyor is more frequent.