Building The Right Conveyor

There are a number of factors to weigh when selecting a conveyor system for process industries. Often, design concepts are foremost in mind – taking into consideration things like layout and optimal throughput. Sometimes overlooked in the course of building out a conveyor system are the individual components of the machinery itself.

In some ways, it might be comparable to buying a new car. You want the right look and performance, but probably don’t base your purchase decision on individual parts within the engine, for example. While a breakdown of your car can be annoying and inconvenient to say the least, it likely doesn’t compare to the impact unexpected downtime of a conveyor system can have on a business that relies on that machinery. Few things kill production like a broken conveyor.

As a result, it’s vital to determine the proper materials for components that best fit your specific conveyor build. This also holds true when repairing or replacing worn parts. Were there factors that led to the previous part breaking down, wearing out or malfunctioning sooner than it should have? Is there a different material or product that will function better?

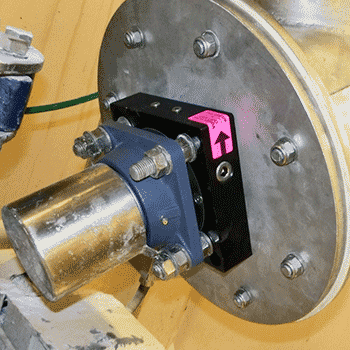

This is particularly relevant to auxiliary components like bearings and seals. The proper selection of these components starts with a comprehensive evaluation of your process parameters. Different applications and environments will call for different materials of construction.

The Importance Of Bearings And Seals

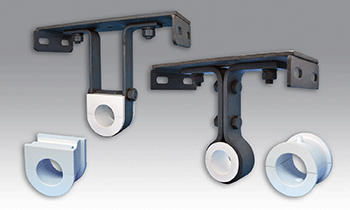

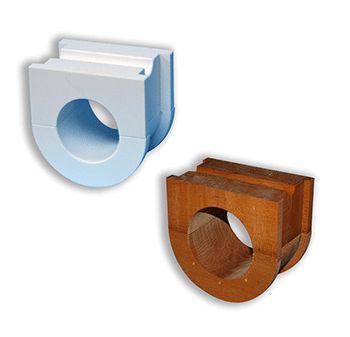

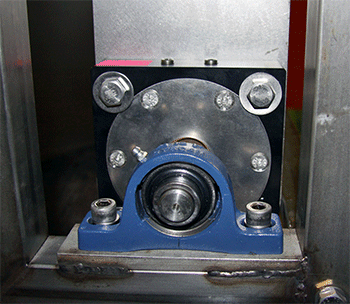

Bearings are at the core of every conveyor system, so it’s imperative you use the proper bearings. One failed bearing can shut down an entire operation. Multiple factors influence the compatibility of your process with materials used in your bearings, which are commonly constructed of plastic, metal, ceramic or wood. Each has its own particular strengths in certain applications. Similar to choosing the right bearing material, the proper seals are also essential to maintain the life of a conveyor and keep it rolling. Many of the same considerations for bearing materials, should also be used when building out the seals. Let’s examine some of the circumstances that factor into choosing the right bearing and seal materials.

Factors For Selecting The Appropriate Component Materials

When specifying the build details of your conveyor, it’s crucial to remember that the compatibility of your component materials with your process environment will influence how well the system performs. Here are some considerations to keep in mind.

Speed And Load

From agriculture to pharmaceuticals to chemicals, across all types of process industries, conveyors run at varying speeds and carry highly variable loads. This has a significant impact on the machine’s bearings. The mechanical physics of load and speed on bearings can get rather complex. Formulas exist to measure the ability of a bearing material to accommodate the temperature generated by the frictional movement of operation. We won’t dive that deep into the mathematics here, but will make the point that different bearing materials have different maximum speed and load values. Some may offer higher maximum load, but lower maximum velocity. The key is making sure your bearing material adequately supports the combination of these factors.

Speed and load also impact wear inside the shaft. Rough shafts can file away at the bearing’s surface, particularly at high speeds. However, shafts that are too smooth can actually generate friction because the bearing and shaft will adhere to one another. The condition of a shaft will have an impact on the wear of the bearings.

Lubrication

Some bearing materials offer self-lubricating characteristics. Others require a continuous supply of lubricant during operation. The need for a lubricant adds complexity to a system by potentially requiring a pump, controls, piping or other components to supply the lubricant. This, of course, also increases the cost and potential for process malfunction.

Some seals may also require a liquid or lubricating barrier for cooling. That could be a problem in dry bulk processing applications, for example.

Dust And Dry Powders

Many process industries involve dusty or gritty conditions. Agriculture is a prime example. As you can imagine, the presence of dust, dirt, pollen and other powdery substances infiltrating and accumulating on moving parts can be detrimental to their function. Certain bearing materials and seal types are better at withstanding such conditions.

Wet Conditions

Almost the opposite, but in a similar manner to the presence of dust and dry contaminants, the presence of moisture and water or other liquids also affects the bearing material. Some bearings may be completely submerged during operation, and must withstand that environment. Other situations might find the bearings operating out of water, but in a highly moist or humid environment, which can have a swelling effect on some materials.

Even bearings used in dry processes sometimes require washdown procedures, which will subject them to wet conditions and, potentially, our next consideration: chemicals.

Presence Of Chemicals

The presence of chemicals in your process will also impact your ideal choice of bearing and shaft seal materials. Whether these chemicals are part of normal procedure, or if they’re introduced in times of washdown, how will they react with the materials in your bearings and seals? Are the chemicals abrasive to metals? Corrosive to plastics?

Will the conveyor be processing potentially explosive materials? If so then shaft seals and other components that create heat or static electricity should be configured to process the materials safely. Some seals require a liquid barrier for cooling, which is usually unacceptable in dry bulk processing applications. Also consider that components engineered for explosion prevention can take longer to source and manufacture, so that time should be factored in during the planning stages.

Noise

Machinery is often loud. Sometimes it’s necessary or helpful to reduce the noise emitted where possible. Bearing material can have an influence on noise. Small load, high-speed shafts might produce a high-pitched ring with metal bearings, which could be reduced by a softer material – assuming that different material fits other necessary considerations as previously discussed. Some bearing materials do provide noise-dampening properties

Cost

No smart decision in business is made without weighing the cost, and bearing materials can vary widely in cost and availability.

In certain situations, the price of a bearing or shaft seal may not be relative to its performance. Just because it’s the most expensive doesn’t mean it’s right for your situation. Compatibility of the components materials are as important, if not more important, than cost. Choosing a less expensive option that isn’t compatible with your process will cost you more in the long run through downtime, more frequent MRO and lost production.

Evaluating And Planning

When specifying the build details of your conveyor, remember to determine the compatibility of the materials of construction of the auxiliary conveyor components and how they will perform in your process with your process materials.

The compatibility of bearing materials, valves, seal type and internal seal components such as metals, plastics and elastomers, and how they are affected by the process materials, will help extend the life of the components and give better conveyor performance. Taking the time to conduct a thorough evaluation of your process and the environment of your conveyor system, will help you determine the best materials for its construction and operation. This will, in turn, provide optimum performance, the least downtime and, ultimately, the best return on investment. It’s also important to understand the availability of replacement components. Parts for conveyors designed following Conveyor Equipment Manufacturers Association (CEMA) standards are more readily available, but custom builds are commonplace and replacement components for these machines can have much longer lead times. Prudent planning and investigation before a conveyor is purchased is important, and understanding all the design considerations covered here can help you get the perfect machine for your needs.

A Consideration Of Materials

It’s probably common for most people to think of bearings as metal assemblies, but there are other options when it comes to bearing construction, and they vary greatly in their properties. Softer materials, such as high-performance plastics, have gained popularity in certain processes. Their strengths include a broad range of chemical resistance, strength and lubricity. High-performance plastics are often FDA approved materials and can be offered fully split.

Wood, plastic, ceramic and rolling element bearings also each have characteristics that make them perform best in a given process. Lubricated wood, for example, is a very shaft-friendly material, especially in agricultural or abrasive processes. When an abrasive material invades the journal interface of a lubricated wood bearing, it compresses, absorbing the pollutant into its surface, and covering it with a film of oil. The abrasive that typically destroys a shaft becomes a benign part of the bearing. The wood releases lubricant when the shaft begins to spin and the journal interface heats; when the shaft stops and the journal cools, the natural capillary action of the wood retrieves the lubricant.

Keep in mind the abrasiveness, chemical properties and temperature of the process materials. Is the process food grade? Will the conveyor process multiple, varied materials with different properties? All of the chemical, abrasive and temperature specifications also will affect seal performance and life.

Also keep in mind your washdown procedures. How often will the conveyor be cleaned and what chemicals will be involved? Would a stainless steel, aluminum, or nylon seal be most compatible with your washdown chemicals? These considerations also will affect the choice of other auxiliary pieces such as valves, gauges, regulators, etc.

Order Early

Whether you are planning a new equipment build or looking to replace a seal on existing equipment, it is important to evaluate your timeline for delivery, or your maintenance shut-down schedule, in order to maximize efficiency. This being said, order early! It is easier to request a “do not ship before” date, as opposed to waiting until the dates align with the approximate lead time on a proposal. By waiting to get into a manufacturer’s production queue, you run the risk of not meeting your scheduled deadlines. Be aware that the clock doesn’t start ticking on your purchase order until the formal approval drawings are signed. Manufacturers of custom seals, for example, typically do not place orders for raw materials until after this time. Additionally, quality control is not passed until the seal is entirely manufactured and assembled.

Prudent planning before you order any new equipment and allowing time for review and approval of design specifications, including the abrasiveness, chemical properties, flow characteristics and temperature of your process and process materials, will help get you the conveyor that works best for your situation right out of the box.

Original post: https://www.mecoseal.com/resources/screw-conveyor-builds/