Why Choose Ribbon Mixers?

Superior Mixing Performance

Ribbon mixers are renowned for their superior blending capabilities. Featuring a unique design with inner and outer helical ribbons rotating in opposing directions, these mixers create a fluidized action that ensures thorough and uniform mixing of powders, granules, and pastes. This design minimizes segregation and achieves consistent product quality, making ribbon mixers ideal for a wide range of applications.

Versatility Across Applications

Ribbon mixers offer exceptional versatility, making them suitable for various industries and applications. Whether you need to mix food ingredients, pharmaceutical powders, chemical compounds, or other bulk materials, ribbon mixers can handle it all. Their adaptable design accommodates different material characteristics and processing requirements, making them a universal solution for your mixing needs.

Sustainable and Cost-Effective

In today’s eco-conscious world, sustainability is a key consideration. Ribbon mixers align with modern environmental standards by operating at lower speeds, reducing energy consumption, and minimizing wear and tear on components. Their efficient mixing action not only conserves resources but also reduces processing times, contributing to a lower carbon footprint and operational cost savings.

Key Benefits of Our Ribbon Mixers

- Efficient Mixing: Achieves homogeneous mixtures quickly and effectively.

- Energy Savings: Operates at lower speeds, reducing energy usage.

- Reduced Downtime: Easy maintenance and cleaning for minimal operational interruptions.

- Durable Construction: Built to last with high-quality materials ensuring long-term performance.

- Customizable Options: Available with various features to suit your specific needs, including different sizes, materials, and additional functionalities.

Applications of Ribbon Mixers

Ribbon mixers are versatile tools used in numerous industries, including:

- Food Processing: Ideal for blending ingredients in the production of baked goods, snacks, and powders.

- Pharmaceuticals: Ensures consistent mixing of active ingredients and excipients in drug formulations.

- Chemicals: Efficiently combines chemical powders and granules for various industrial processes.

- Plastics and Polymers: Mixes additives and fillers to enhance the properties of plastic products.

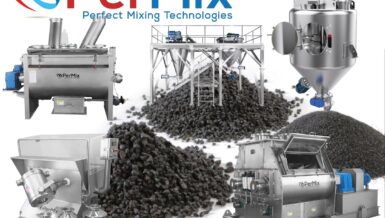

Why PerMix?

At PerMix, we are committed to providing high-quality ribbon mixers that meet the highest industry standards. Our team of experts works closely with you to understand your unique requirements and deliver tailored solutions that optimize your mixing processes. With a focus on innovation, efficiency, and customer satisfaction, we ensure that our ribbon mixers not only meet but exceed your expectations.