Some manufacturers have invested substantial resources in high-speed mixing and packaging lines to achieve high throughput. However, many more factors such as below should be considered first in order to find a more optimal mixing solution.

Factors to consider:

- Batch or continuous process

- Characteristics of the powder

- Batch size and batch size demands

- Overall Mixing time

- Changeover time

- Ease of cleaning and CIP system

- Cross-contamination risk

- Segregation risk after mixing

- Horizontal and vertical factory space

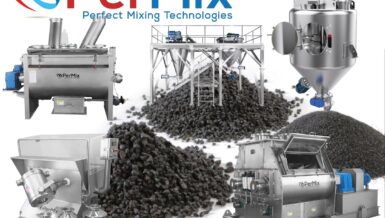

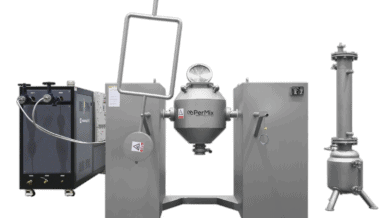

- Proper blender selection

Features of CPE Powder Blenders

- Large hatch inspection doors

- Load cell brackets

- Compatible for CIP

- Fast acting bomb bay door discharge system incorporating pneumatic actuation and FDA certified seal materials (ATEX and CE standards available)

- Flat leading face paddle profile

- Minimal guards easing access for cleaning

- Round body design offering greater strength

- C Series Retractable – Retractable rotor design

- CHDV – Capability to vacuum feed without space required for hopper for gravity feeding