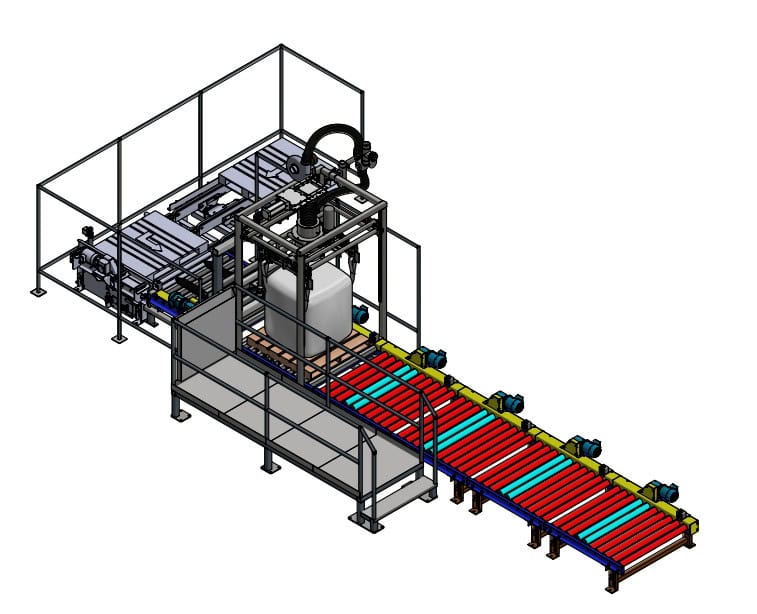

With advanced features and robust construction, the BagPak 4400-AD ensures faster fill times, reduced waste, and improved bag stability, making it an essential addition to any bulk material packaging process.

Key Features & Benefits

One of the standout features of the BagPak 4400-AD is its Automatic Densification (AD) system, which enhances the quality and stability of filled bags. During the filling process, the system compacts materials, eliminating excess air pockets and ensuring an even distribution of product.

This minimizes voids, improves bag stability, and significantly reduces settling during storage and transportation. With more uniform and compact bags, companies can optimize palletizing, reduce product loss, and improve handling efficiency.

Another advantage of the BagPak 4400-AD is its precision weighing technology, which ensures accurate and consistent bag fills. Overfilling or underfilling bulk bags can lead to product waste, inefficiencies, and added costs. By integrating advanced weight controls, this system guarantees that each bag meets exact specifications, preventing material loss while maintaining operational efficiency.

Lastly the Easy-Attach & Release lift loop carousel provides operators with ergonomic attachment of empty bags, as well as auto-release and full bag accumulation.

Designed for High-Speed Operations

For facilities that require high-speed, high-volume bagging, the BagPak 4400-AD is built to keep up with demand. Its streamlined design allows for quick bag changes and seamless operation, reducing downtime and maximizing throughput. Typically this system can deliver between 12-24 bags per hour (depending on material characteristics and upstream delivery). The rugged frame and durable components ensure long-term reliability, even in the most demanding industrial environments.

Additionally, the system features a user-friendly interface, making it easy for operators to adjust settings, monitor performance, and maintain optimal efficiency with minimal training. Its automated processes not only improve accuracy but also reduce the need for manual labor, lowering the risk of human error and increasing workplace safety.

A Smarter Bulk Bagging Solution

Whether you are looking to increase productivity, improve product consistency, or reduce waste, the BagPak 4400-AD delivers an innovative and highly efficient solution. By incorporating advanced densification, precision weighing, and high-speed operation, this system ensures that businesses can optimize their bulk bagging process with confidence. Experience the future of bulk material packaging with FormPak Inc. ’s BagPak 4400-AD—a smarter, faster, and more efficient way to handle bulk bagging.