The material and data can be continuously tracked. BEUMER Group optimizes the performance of each machine, its components and the high-level controls to ensure high throughput of the lines.

The behavior of powders and bulk material can change entirely according to operating conditions, handling methods and the intended use. This impacts the flow behavior, which has a considerable influence on how to optimally design the conveying, filling, palletizing and packaging systems. BEUMER Group designs constructs and installs systems that are tailored in detail to industry-specific requirements.

The BEUMER fillpac R filling machine fills bulk material from the building materials industry and other industrial pulverized goods into different bag sizes and types like valve bottom and flat valve bags in an efficient and gentle way and with the required throughput. The structure of the materials can be very fine to very coarse. The BEUMER bag placer and the ream magazine supply the rotary filling machine with empty bags to ensure the high throughput.

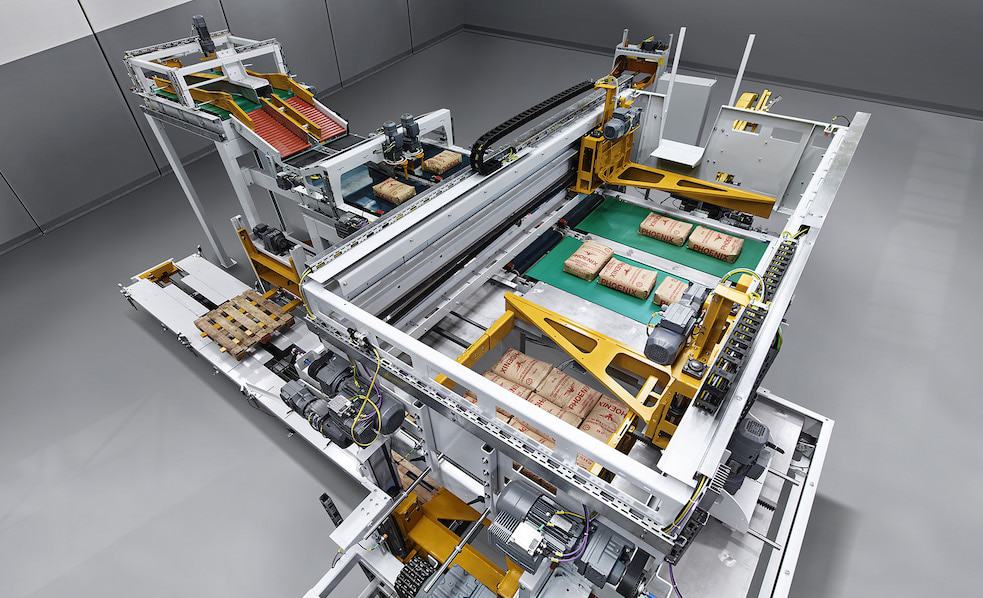

BEUMER Group offers different palletizing solutions, depending on the packaged items. The BEUMER paletpac is suited best for bagged bulk material. It is incorporated into high-performance packaging lines to process even sensitive and valuable products as well as products with special flow characteristics in a gentle and efficient manner. Depending on the product requirements, these palletizers can be equipped with a clamp-type or twin-belt turning device which turns the filled bags quickly into the required position for stacking, ensuring their dimensional stability without any deformations.

Several products of the (petro)chemical industries are filled in special bags, barrels, canisters, cartons or buckets. To palletize them, BEUMER Group offers its space-saving articulated robot, the BEUMER robotpac. Depending on the packaged items, BEUMER Group equips the robot with the appropriate gripping tools which can be easily and automatically changed, if the packaged items change. The fork gripper, for example, was designed specifically for palletising cardboard boxes, the finger gripper for bagged goods. For maximum performance, BEUMER Group offers a double gripper for both types. They also offer parallel grippers for dimensionally stable packed items, suction grippers for items with a smooth surface and many other special grippers and combination tools.

Packaged items stacked accurately on pallets can then be transported successfully to the downstream packaging system – for example, the BEUMER stretch hood. It covers the palletized goods with a highly stretchable film. During transshipment and outside storage, the merchandise is protected reliably against environmental influences such as sunlight, dirt, and humidity.