POLİMAK‘s Big Bag Filling Systems are engineered to optimize the handling and filling of big bags, ensuring maximum efficiency, safety, and sustainability. With our system, different types of bulk materials can be handled, ranging from free-flowing granules to poorly flowing, sticky fine powders. This versatility enables the system to be used across various industries, including chemicals, food, plastics, and agriculture.

The working principle of a typical Big Bag Filling System is as follows:

Minimizing Waste: The continuous recycling of dust back into the cyclone minimizes material loss, enhancing operational efficiency and sustainability.

Vacuum Conveying by Blower: The bulk material is transported through a pipeline using suction created by a blower, which vacuums the material.

Material Conveying to Cyclone: The conveyed material is directed into a cyclone, where air and particles are separated. The cyclone serves as a separator for dust and bulk material.

Discharge into Big Bags: The product inside the cyclone is then discharged into FIBCs or octabins through a rotary valve, which controls the flow of material.

Dust Generation and Collection: During the filling process, dust particles are generated and captured by a dust collection system designed to minimize airborne dust.

Return of Dust to Cyclone: The dust captured by the dust collection system is then returned to the cyclone and reintroduced into the product flow, reducing product waste.

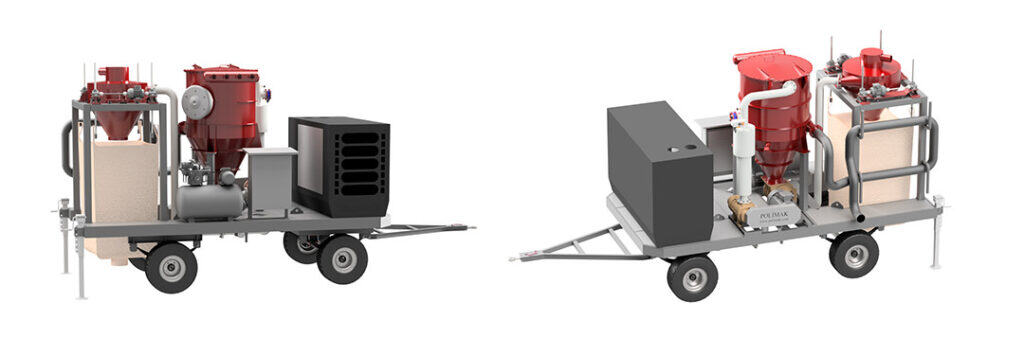

In addition to the configuration described above, POLİMAK engineers have also developed a Mobile Bulk Bag Filling System, offering the added benefit of mobility in big bag handling solutions. Perfect for on-site, mobile operations, these systems enhance sustainability and reduce material waste.

The Benefits of Polimak Big Bag Filling Systems:

- The optional mobile setup guarantees on-site movement and operation.

- Promotes sustainability by reducing waste and energy consumption.

- Provides cost-effectiveness through efficient operation and low maintenance.

- Ensures a safe and clean working environment.

- Maintains a dust-free environment and air quality.

- Allows for simple handling of big bags.

- Compatible with various conveying and storage systems.

- Offers a wide range of models for different applications.

- Designed for easy cleaning.

- Features a maintenance-free design for smooth operation.

- Built with a rigid, steel construction for durability.

- Includes a filter system to prevent dust from escaping.

- The optional mobile setup guarantees on-site movement and operation.

POLİMAK’s Big Bag Filling Systems are designed for a wide range of applications, particularly in the food, chemicals, mining, plastics, and cement industries. With over 40 years of know-how and technical expertise, we deliver high-quality, reliable, safe, and cost-effective solutions for big bag filling systems. By following the core principles of the bulk handling industry — such as sustainability, efficiency, and safety — we provide tailored, industry-specific solutions to meet the unique demands of each sector.