The key facts

- Filling capacity: 50 tons/hour

- Scale resolution of 100 g for a filling quantity of 1000 kg

- Robust weighing electronics

- PROFINET connection

- Fast implementation of filling systems through EMDE

Products

- IT8000E: Versatile and robust SysTec weighing terminal for continuous operation

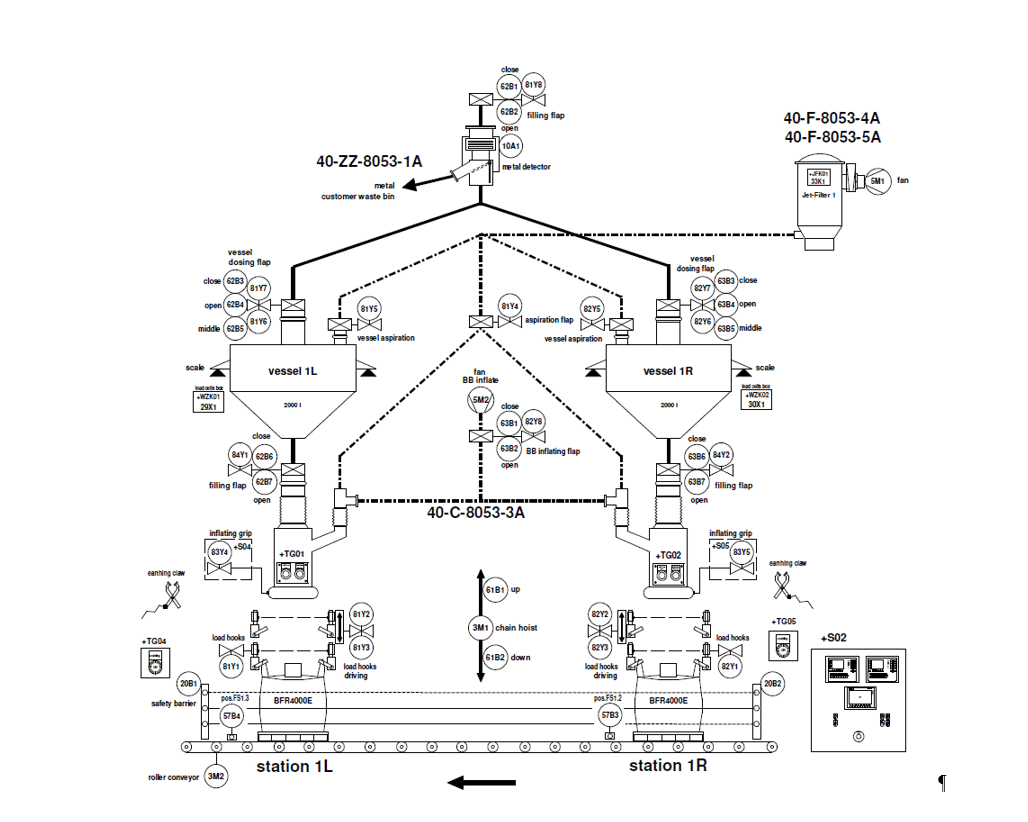

- SysTec application software BIG BAG E for rapid filling

- EMDE double filling system with roller conveyors for moving of big bags

Customer benefits

- High throughput with double filling stations – fast and precise weighing technology

- Fast operation via precise filling systems

- Efficient control system

- Intuitive operation for personnel

- Connection to third-party systems, e.g. to a warehouse management system as well as to a higherlevel control system to which weighing data are sent for visualization in control rooms

The customer

With 5100 employees in over 70 countries, BEUMER offers intralogistics solutions in the areas of conveying, loading, palletizing, packaging, sorting and distribution. Apart from the chemical industry, BEUMER is active in sectors such as baggage handling, construction materials, mining, ports, and e-commerce.

The material to be filled – plastic granules

In the double filling station, LLDPE (Linear Low Density Polyethylene), HDPE (High Density Polyethylene) and PP (Polypropylene) granules are weighed and filled into big bags. By melting the granules, they can be converted into numerous end-use applications such as plastic bottles, packaging foil, cable sheathing, cell phone housings and technical fibers

IT8000E weighing terminal with application program

- High operating convenience: simple multilingual operator prompting, bright 5.7“ TFT color display with wide viewing angle and large weight display; alphanumeric keyboard

- W&M approved as non-automatic and automatic scale, (approved in EC, USA, Canada, etc.)

- Universal use: Numerous standard application programs

- Custom-specific adaptations: Free programmability

- Robust: Stainless steel housing (protection class IP69K)

- Ex-area: For hazardous areas SysTec offers the version IT8000E Ex2/22 and for zones 1/21 the version IT8000Ex

- Several housing options: Wall-mount / desk-top version as well as version for panel-mount installation

- Numerous interfacing options: 2 internal and up to 6 external scale connections, can be integrated into PC networks via Ethernet or WLAN, connection to label & network printer, PLC connection via fieldbus

- High operational security: Powerfail-safe data storage, password protection, battery-backed real-time clock, remote diagnosis via internet possible

“Due to the easy integration into our systems and thanks to the intuitive handling by the plant operators, the W&M approved and internationally certified SysTec weighing terminals are very well suited for our worldwide projects.“