In addition, we also supplied the components and systems, including special-duty rotary valves, suitable for handling lactose.

Project

Raw materials for pizza cheese are made at the company’s factory in Ireland. In order to cope with the increasing demand for these products, it was necessary to carry out a complete renovation and upgrade of the existing dilute phase production lines for whey protein and lactose. This concerned the route from the existing spray dryers and a new spray dryer to the packaging machines. After the upgrade, the lines had to comply with the applicable EHEDG and ATEX guidelines.

Solution

TBMA has installed new, fluidizing discharge systems and new, larger filter units on the existing silos. The pneumatic conveying lines were fitted with new, hygienic rotary valves and diverter valves. In addition, a great deal of attention was paid to the cleanability of the installation and an increase of the production availability between service interventions.

Moreover, TBMA installed new receiving hoppers with air filters and fluidization in one of the hi-care packaging areas. Two TBMA high-care Big-Bag filling stations are located in a second hi-care packaging area, complete with roller tracks, vibrating scissor lift, weighing unit and dosing system, in addition to the existing bag filling line for filling 25 kg bags.

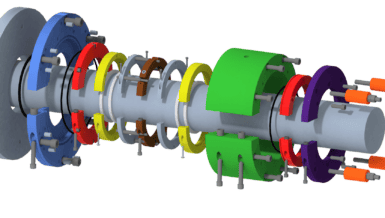

Rotary valves with guarded air lock seal

This system detects any problems in an early stage, thus facilitating adequate preventive maintenance and virtually avoiding production downtime. The valves are equipped with a special rotor with minimal friction surfaces. Critical valves are of a mobile design to enable a quick change and wet cleaning or maintenance outside the production environment. By using the new special-duty TBMA rotary valves, the production time between service is now approximately one year.

Implementation

Pneumatic conveying systems transfer the powders from the spray dryers to the selected silos, where the conveying air is separated via primary and secondary dust filters. The silos are equipped with load cells, level detectors and safety valves against unwanted overpressure.

The fluidisation systems in the silo cones ensure that the rotary valves are optimally fed. These valves then ensure that the correct amount of product is dosed into the pneumatic conveying system, which conveys the product to the buffer hoppers in the packaging area. The product passes through a sieve and metal detection and can be sampled in-line before it is transferred to the sack or big-bag.

The conveying blowers are frequency controlled so that an air flow is maintained even when there is no product demand. This ensures that the air quality in the pipelines remains at an optimum level. A PID control of the rotary valve speed based on the conveying line pressure ensures that an optimum conveying rate is achieved, and pipe blockages are avoided.

When filling Big-Bags the operator suspends a new bag on the self-releasing hooks, after which the filling spouts is connected to the machine filling head. An inflatable seal maintains dust-free conditions in the high-care area. The Big-Bag is inflated by conditioned air so that the internal liner and the outer bag have the same shape. During filling the Big-Bag is vibrated by a special design table, which is raised and lowered during the coarse fill cycle. This action, coupled with the suspended big-bag, ensures that the bag is repeatedly stretched thereby creating a stable, optimally filled big-bag. During the final phase (fine dosing) the Big-Bag hangs completely on the weighing frame so that accurate weighing is possible. The combination of accurate weighing and fine dosing assures repeatability of the big-bag weights. Certification of the filling machine as a commercial weighing unit by “Weights & Measures” is then simplified.

TBMA has a complete range of components and systems to offer solutions beyond bulk handling Check out our website for information about systems for pneumatic conveying or Big-Bag filling, as well as rotary valves, diverter valves and samplers.

Data

- Product: lactose, skimmed milk powder, buttermilk powder and whey proteins (WPC)

- Pneumatic transport: 15.000 kg per hour

- Buffer hoppers: 5 m3

- Filling capacity: 15 Big-Bags per hour

Components and systems

- Fluidization systems for silos

- Filter systems for silos

- Pneumatic transport systems from the storage silos to the packaging lines

- Diverters and shut-off valves

- Hygienic rotary valves (lactose version)

- 3 buffer hoppers with 5 m3 capacity

- Hi-care Big-Bag filling lines with vibrating table and precise weighing

- In-line hygienic sampler

- Roller tracks with scissor lift, control panels and software

- Project design and engineering